Research Activity

List of recent publications

#### 2024

1. X. Li, J. Chen, Y. Yang, H. Cai, Q. Huang, Z. Ao, Y. Xing, K. Li, K. Yang, A. Wallace, J. Friend, L. P. Lee, and F. Guo. Extracellular vesicle-based point-of-care testing for diagnosis and monitoring of Alzheimer's disease. *Microsystems \& Nanoengineering (Nature)*, **Accepted 11 December**2024.

1. L. Zhang, S. Zhang, C. Floer, S. Kantubuktha, M. Velasco, and J. Friend. Surface acoustic wave-driven enhancement of enzyme-linked immunosorbent assays: ELISAW. *Analytical Chemistry (ACS Editors' Choice)*, **96**(23):9676-9683, 2024.

1. P. Truong, E. H. Walsh, V. P. Scott, M. Leff, A. Chen, and J. Friend. Application of statistical analysis and machine learning to identify infants' abnormal suckling behavior. *{IEEE} Journal of Translational Engineering in Health and Medicine*, **12**:435-447, 2024.

1. D. Santiago-Dieppa and J. Friend. Endovascular microrobotics for neurointervention. *Annual Review of Control, Robotics, and Autonomous Systems*, **7**(385-408)2024. https://doi.org/10.1146/annurev-control-060523-010720

1. W. Connacher, J. Orosco, O. Schmidt, and J. Friend. Direct observation of small scale capillary wave turbulence using high speed digital holographic microscopy. *Frontiers in Acoustics*, **2**(1512579):1-13, 2024.

#### 2023

1. A. Horesh, W. Connacher, and J. Friend. Acoustothermal phase change and acoustically driven atomization for cold liquid microthrusters. *Applied Physics Letters*, **122**(014104):1-7, 2023. https://doi.org/10.1063/5.0131467

1. K. Nguyen, L. Zhang, and J. Friend. Acoustofluidics. *Acoustics Today*, **19**(2):36-44, 2023.

1. A. Vasan, U. Magaram, J. Patel, J. Friend, and S. Chalasani. Integrating ultrasound-induced neural activity modulation with fiber photometry. *Frontiers in Acoustics*, **1**(1326759):1-9, 2023.

1. O. Dubrovski, J. Friend, and O. Manor. Theory of acoustic streaming for arbitrary Reynolds number flow. *Journal of Fluid Mechanics*, **975**(A4):1-22, 2023. https://doi.org/10.1017/jfm.2023.790

1. S. C. Johns, P. Gupta, Y.-H. Lee, J. Friend, and M. M. Fuster. Glycocalyx transduces membrane leak in brain tumor cells exposed to sharp magnetic pulsing. *Biophysical Journal*, **122**:4425-4439, 2023. https://doi.org/10.1016/j.bpj.2023.10.020

1. J. Friend. Acoustofluidics. *Frontiers in Acoustics*, **1**(1261027):1-8, 2023.

1. J. Orosco and J. Friend. Identification of weakly to strongly-turbulent three-wave processes in a micro-scale system. *Chaos, Solitons & Fractals*, **172**(113615):1-7, 2023. https://authors.elsevier.com/sd/article/S0960-0779(23)00516-7

1. Y. Zhou, N. Zhang, D. J. Bisharat, R. J. Davis, Z. Zhang, J. Friend, P. R. Bandaru, and D. F. Sievenpiper. On-chip unidirectional waveguiding for surface acoustic waves along a defect line in a triangular lattice. *Physical Review Applied*, **19**(2)2023. https://doi.org/10.1103%2Fphysrevapplied.19.024053

1. S. Zhang, J. Orosco, and J. Friend. Onset of visible capillary waves from high-frequency acoustic excitation. *Langmuir*, **39**(10):3699-3709, 2023. https://doi.org/10.1002/smll.202204288

#### 2022

1. J. Orosco and J. Friend. Modeling fast acoustic streaming: steady-state and transient flow solutions. *Physical Review E*, **106**(045101):1-17, 2022. https://doi.org/10.1103/PhysRevE.106.045101

1. C. Imashiro, J. Mei, J. Friend, and K. Takemura. Quantifying cell adhesion through forces generated by acoustic streaming. *Ultrasonics Sonochemistry*, **90**(106204):1-8, 2022. https://doi.org/10.1016/j.ultsonch.2022.106204

1. M. Li, J. Mei, J. Friend, and J. Bae. Acousto-photolithography for programmable shape deformation of composite hydrogel sheets. *Small*, ****(2204288):1-10, 2022. https://doi.org/10.1002/smll.202204288

1. J. Mei, A. Vasan, U. Magaram, K. Takemura, S. H. Chalasani, and J. Friend. Well-free agglomeration and on-demand three-dimensional cell cluster formation using guided surface acoustic waves through a couplant layer. *Biomedical Microdevices*, **24**(18):1-13, 2022. https://doi.org/10.1007/s10544-022-00617-z

1. J. Bravo, A. R. Wali, B. R. Hirshman, T. Gopesh, J. A. Steinberg, B. Yan, J. S. Pannell, A. Norbash, J. Friend, A. A. Khalessi, and D. Santiago-Dieppa. Robotics and artificial intelligence in endovascular neurosurgery. *Cureus*, **14**(3):e23662, 2022.

1. J. Rufo, F. Cai, J. Friend, M. Wiklund, and T. Huang. Acoustofluidics for biomedical applications. *Nature Reviews Primers*, **2**(30):1-21, 2022. https://rdcu.be/cLN7Z

1. M. Duque, C. Lee-Kubli, Y. Tufail, U. Magaram, J. M. Lopez, E. Edsinger, A. Vasan, R. Shiao, C. Weiss, J. Friend, and S. H. Chalasani. Sonogenetic control of mammalian cells using exogenous transient receptor potential a1 channels. *Nature Communications*, **13**(600):1-17, 2022.

1. A. Vasan, F. Allein, M. Duque, U. Magaram, N. Boechler, S. H. Chalasani, and J. Friend. Microscale concert hall acoustics to produce uniform ultrasound stimulation for targeted sonogenetics in hstrpa1-transfected cells". *Advanced NanoBiomed Research*, **2**(2100135):1-9, 2022. http://dx.doi.org/10.1002/anbr.202100135

1. U. Magaram, C. Weiss, A. Vasan, K. C. Reddy, J. Friend, and S. H. Chalasani. Two pathways are required for ultrasound-evoked behavioral changes in caenorhabditis elegans. *PLoS One*, **17**(5):1-12, 2022. https://doi.org/10.1371/journal.pone.0267698

1. J. Wang, F. Allein, C. Floer, N. Boechler, J. Friend, and O. V. Mena. Negative-index acoustic metamaterial operating above 100 khz in water using microstructured silicon chips as unit cells. *Advanced Materials Technologies*, (2200407):1-11, 2022. https://doi.org/10.1088/1361-6439/abbcba

#### 2021

1. G. Tilvawala, A. Grant, J. H. Wen, T. H. Wen, E. Criado-Hidalgo, W. J. Connacher, J. R. Friend, and T. Morris. Vacuum exhausted isolation locker (VEIL) to reduce inpatient droplet/aerosol transmission during COVID-19 pandemic. *Infection Control & Hospital Epidemiology*, **43**(1):1-10, 2021.

1. N. Zhang, A. Horesh, C. Floer, and J. Friend. Unapodization: a method to produce laterally uniform surface acoustic waves for acoustofluidics. *Journal of Micromechanics and Microengineering*, **31**(104001):1-12, 2021. https://doi.org/10.1088/1361-6439/ac1d2d

1. A. Vasan, J. Orosco, U. Magaram, M. Duque, C. Weiss, Y. Tufail, S. H. Chalasani, and J. Friend. Ultrasound mediated cellular deflection results in cellular depolarization. *Advanced Science*, **9**(2):1-12, 2021.

1. T. Gopesh, J. H. Wen, D. Santiago-Dieppa, B. Yan, J. S. Pannell, A. Khalessi, A. Norbash, and J. Friend. Soft robotic steerable micro-catheter for the endovascular treatment of cerebral disorders. *Science Robotics*, **6**(eabf0601):1-14, 2021.

1. A. Huang, W. Connacher, M. Stambaugh, N. Zhang, S. Zhang, J. Mei, A. Jain, S. Alluri, V. W. Leung, A. Rajapaksa, and J. Friend. Practical microcircuits for handheld acoustofluidics. *Lab on a Chip*, **21**(7):1352-1363, 2021. https://doi.org/10.1039/D0LC01008A

1. N. Zhang, A. Horesh, O. Manor, and J. Friend. Powerful acoustogeometric streaming from dynamic geometric nonlinearity. *Physical Review Letters*, **126**(164502):1-5, 2021. https://doi.org/10.1103/PhysRevLett.126.164502

1. N. Zhang, J. P. Zuniga-Hertz, E. Y. Zhang, T. Gopesh, M. J. Fannon, J. Wang, Y. Wen, H. H. Patel, and J. Friend. Microliter ultrafast centrifuge platform for size-based particle and cell separation and extraction using novel omnidirectional spiral surface acoustic waves. *Lab on a Chip*, **21**:904-915, 2021.

1. N. Zhang, A. Horesh, and J. Friend. Manipulation and mixing of 200 femtoliter droplets in nanofluidic channels using mhz-order surface acoustic waves. *Advanced Science*, **8**(2100408):1-12, 2021. https://doi.org/10.1002/advs.202100408

1. N. Ashari, M. Kong, A. Poudel, J. Friend, and A. Hargens. Generating waist area-dependent ground reaction forces for long-duration spaceflight. *Journal of Biomechanics*, **118**(110272):1-5, 2021.

1. T. Inui, J. Mei, C. Imashiro, Y. Kurashina, J. Friend, and K. Takemura. Focused surface acoustic wave locally removes cells from culture surface. *Lab on a Chip*, **21**(7):1299-1306, 2021. https://doi.org/10.1039/D0LC01293A

1. J. Friend, C. Thompson, K. Chitale, and M. Denis. Editorial for special issue on acoustofluidics: introduction to the special issue on the theory and applications of acoustofluidics. *Journal of the Acoustical Society of America*, **150**(4558):1-4, 2021.

1. A. Singh, N. Zhang, and J. Friend. An investigation of maximum particle velocity as a universal invariant --- defined by a statistical measure of failure or plastic energy loss for acoustofluidic applications. *Journal of the Acoustical Society of America*, **150**(2):878-890, 2021.

#### 2020

1. J. Mei and J. Friend. A review: controlling the propagation of surface acoustic waves via waveguides for potential use in acoustofluidics. *Bulletin of the Japanese Society of Mechanical Engineers*, **7**(1):1-25, 2020.

1. J. Wang, F. Allein, N. Boechler, J. Friend, and O. V. Mena. Design and fabrication of acoustic unit cells for negative refractive index metamaterials for near-megahertz enhanced acoustic transmission in future biomedical ultrasound applications. *Physical Review Applied*, **Accepted 24 November** 2020.

1. W. Connacher, J. Orosco, and J. Friend. Droplet ejection at controlled angles via acoustofluidic jetting. *Physical Review Letters*, **125**(18)2020. https://link.aps.org/doi/10.1103/PhysRevLett.125.184504

1. A. Huang, H. Liu, O. Manor, P. Liu, and J. Friend. Enabling rapid charging lithium metal batteries via surface acoustic wave‐driven electrolyte flow. *Advanced Materials*, **32**:1907516, 2020. http://dx.doi.org/10.1002/adma.201907516

1. A. Vasan, W. Connacher, and J. Friend. Fabrication and methods of characterization of thickness mode piezoelectric devices for atomization and acoustofluidics. *Journal of Visualized Experiments*, **162**(e61015)2020. https://dx.doi.org/10.3791/61015

1. N. Zhang and J. Friend. Fabrication of nanoheight channels incorporating surface acoustic wave actuation via lithium niobate for acoustic nanofluidics. *Journal of Visualized Experiments*, **156**:e60648, 2020.

1. J. Mei, N. Zhang, and J. Friend. Fabrication of surface acoustic wave devices on lithium niobate. *Journal of Visualized Experiments*, ****(160):e61013, 2020. https://dx.doi.org/10.3791/61013

1. J. Wang, J. Mei, J. Friend, and O. V. Mena. Frequency and damping effect of suspended silicon nitride membranes fully immersed in water near the megahertz range. *Journal of Micromechanics and Microengineering*, **Accepted 23 September**2020. https://doi.org/10.1088/1361-6439/abbcba

1. A. Phan, P. Truong, C. Schade, A. Vasan, J. Friend, and F. E. Talke. Investigation of long term drift of an intraocular pressure sensor. *Journal of Microsystem Technologies*, **Accepted 23 November**2020.

1. A. Vasan, R. Weekes, W. Connacher, J. Sieker, M. Stambaugh, P. Suresh, D. E. Lee, W. Mazzei, E. Schlaepfer, T. Vallejos, J. Petersen, S. Merritt, L. Petersen, and J. Friend. MADVent: A low-cost ventilator for patients with COVID-19. *Medical Devices and Sensors*, **3**(e10106):1-14, 2020. https://onlinelibrary.wiley.com/doi/abs/10.1002/mds3.10106

1. N. Zhang, Y. Wen, and J. Friend. Mhz-order surface acoustic wave thruster for underwater silent propulsion. *Micromachines*, **11**(4)2020. https://www.mdpi.com/2072-666X/11/4/419

1. A. M. Girgis, M. N. Aziz, T. C. Gopesh, J. Friend, A. M. Grant, J. A. Sandubrae, and D. A. Banks. Novel coronavirus disease 2019 (covid-19) aerosolization box: design modifications for patient safety. *Journal of Cardiothoracic and Vascular Anesthesia*, ****2020. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7201230/

1. N. Zhang, J. Mei, T. Gopesh, and J. Friend. Optimized, omnidirectional surface acoustic wave source: 152 degree y-rotated cut of lithium niobate for acoustofluidics. *{IEEE} Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **67**(10):2176--2186, 2020.

1. C. P. Ashdown, S. C. Johns, E. Aminov, M. Unanian, W. Connacher, J. Friend, and M. M. Fuster. Pulsed low-frequency magnetic fields induce tumor membrane disruption and altered cell viability. *Biophysical Journal*, **118**(7):1552 - 1563, 2020. http://www.sciencedirect.com/science/article/pii/S000634952030134X

1. L. G. Petersen, J. Friend, and S. Merritt. Single ventilator for multiple patients during covid19 surge: matching and balancing patients. *Critical Care*, **24**(357):1-3, 2020. https://doi.org/10.1186/s13054-020-03041-y

1. S. Zhang, A. Huang, A. Bar-Zion, J. Wang, O. V. Mena, M. G. Shapiro, and J. Friend. The vibration behavior of sub-micrometer gas vesicles in response to acoustic excitation determined via laser doppler vibrometry. *Advanced Functional Materials*, **30**(13):2000239, 2020. https://onlinelibrary.wiley.com/doi/abs/10.1002/adfm.202000239

List of older publications (click me)

#### 2019

1. G. Tilvawala, A. Camp, M. Unanian, J. Friend, and R. Weinreb. [**Rapid and accurate intraocular pressure sensing device for patients with artificial corneas**](). Translational Vision Science and Technology, 9(28), 1-9, 2019.

1. A. Vasan and J. Friend. [**Medical Devices for low and middle income countries: A review and directions for development**](https://doi.org/10.1115/1.4045910). ASME Journal of Medical Devices, 14(1):010803, 2019.

1. M. Miansari, M. D. Mehta, J. M. Schilling, Y. Kurashina, H. H. Patel, and J. Friend. [**Inducing Mild Traumatic Brain Injury in C. elegans via Cavitation-Free Surface Acoustic Wave-Driven Ultrasonic Irradiation**](http://em.rdcu.be/wf/click?upn=lMZy1lernSJ7apc5DgYM8dgchTKSYzYGhnHCgKUGwW0-3D_Ay-2B9tXWgrhnQ3z2wVuiTK-2Fa7LxAlkWCTP7Mzj3MvBbcY4nP-2BYyXiqyjH1P65uQNqWjzS3McUpf9bZZQbVPd2I8dADyD7kK0IOAxGTuLJl9zv0P1-2BmCDjF4K28vml6OEibxCP76ivJ1YHvPr3XyMDKQpSNgbWKrmtmjNY6ZkScCa6rRnbVVbD5DmnA3YH-2F-2F1RyygEY7yHy4Xdt2gsESE93JL1TxMfMf1CoKBt8cCvK-2FEvXsiy6ERxHs6EM5bVn-2FajdsihKL9MWD0Th1VMRLWnxg-3D-3D). Scientific Reports, 9(12775)2019.

1. Y. Kurashina, C. Imashiro, M. Hirano, T. Kuribara, K. Totani, K. Ohnuma, J. Friend, and K. Takemura. [**Enzyme-free release of adhered cells from standard culture dishes using intermittent ultrasonic traveling waves**](https://doi.org/10.1038/s42003-019-0638-5). Nature Communications Biology, 2(1):393, 2019.

#### 2014-2018

1. W. Connacher, N. Zhang, A. Huang, J. Mei, S. Zhang, T. Gopesh, and J. Friend. [**Micro/nano acoustofluidics: materials, phenomena, design, devices, and applications**](http://dx.doi.org/10.1039/C8LC00112J). Lab Chip, 18:1952-1996, 2018.

1. S. Collignon, O. Manor, and J. Friend. **Improving and Predicting Fluid Atomization via Hysteresis-Free Thickness Vibration of Lithium Niobate**. Advanced Functional Materials, 28 (1704359) 2018.

1. A. Huang, M. Miansari, and J. Friend. **Driving morphological changes in magnetic nanoparticle structures through the application of acoustic waves and magnetic fields**. Applied Physics Letters, 113(3):034103, 2018.

1. M. Kumaraswamy, S. Collignon, C. Do, J. Kim, V. Nizet, and J. Friend. [**Decontaminating surfaces with atomized disinfectants generated by a novel thickness-mode lithium niobate device**](https://doi.org/10.1007/s00253-018-9088-0). Applied Microbiology and Biotechnology, 15:6459-6467, 2018.

1. Y. Kurashina, K. Takemura, J. Friend, S. Miyata, and J. Komotori. [**Efficient Subculture Process for Adherent Cells by Selective Collection Using Cultivation Substrate Vibration**](http://dx.doi.org/10.1109/TBME.2016.2567647). IEEE Transactions on Biomedical Engineering, 64(3):580-587, 2017.

1. Y. Kurashina, K. Takemura, and J. Friend. **Cell agglomeration in the wells of a 24-well plate using acoustic streaming**. Lab on a Chip, 17(5):876--886, 2017.

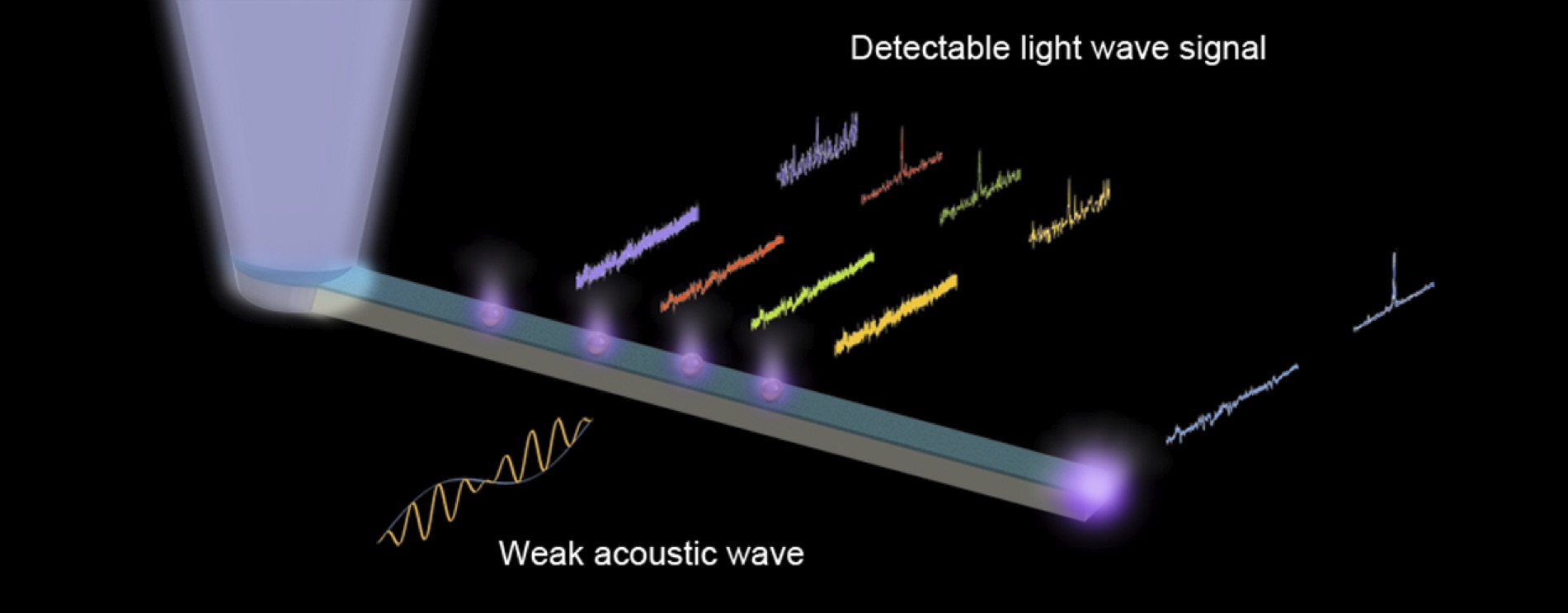

1. Y. Ma, Q. Huang, T. Li, J. Villanueva, N. H. Nguyen, J. Friend, and D. J. Sirbuly. **A Local Nanofiber-Optic Ear**. ACS Photonics, 3(10):1762--1767, 2016.

1. K. M. Ang, L. Y. Yeo, J. R. Friend, Y. M. Hung, and M. K. Tan. [**Acoustically enhanced heat transport**](http://scitation.aip.org/content/aip/journal/rsi/87/1/10.1063/1.4939757). Review of Scientific Instruments, 87(1)2016.

1. M. Miansari and J. R. Friend. [**Acoustic Nanofluidics via Room-Temperature Lithium Niobate Bonding: A Platform for Actuation and Manipulation of Nanoconfined Fluids and Particles**](http://dx.doi.org/10.1002/adfm.201602425). Advanced Functional Materials, 26(43):7861--7872, 2016.

1. M. Miansari, A. Qi, L. Y. Yeo, and J. R. Friend. **Vibration-Induced Deagglomeration and Shear-Induced Alignment of Carbon Nanotubes in Air**. Advanced Functional Materials, 25(7):1014-1023, 2015.

1. C. Cortez-Jugo, A. Qi, A. Rajapaksa, J. R. Friend, and L. Y. Yeo. [**Pulmonary monoclonal antibody delivery via a portable microfluidic nebulization platform**](http://scitation.aip.org/content/aip/journal/bmf/9/5/10.1063/1.4917181). Biomicrofluidics, 9(5), 2015.

1. Y. Wang, J. Z. Ou, A. F. Chrimes, B. J. Carey, T. Daeneke, M. M. Y. A. Alsaif, M. Mortazavi, S. Zhuiykov, N. Medhekar, M. Bhaskaran, J. R. Friend, M. S. Strano, and K. Kalantar-Zadeh. [**Plasmon Resonances of Highly Doped Two-Dimensional MoS2**](http://dx.doi.org/10.1021/nl503563g). Nano Letters, 15(2):883-890, 2015.

1. S. Collignon, J. Friend, and L. Yeo. [**Planar microfluidic drop splitting and merging**](http://dx.doi.org/10.1039/C4LC01453G). Lab Chip, , 2015.

1. K. M. Ang, L. Y. Yeo, J. R. Friend, Y. M. Hung, and M. K. Tan. **Nozzleless spray cooling using surface acoustic waves**. Journal of Aerosol Science, 79:48-60, 2015.

1. J. E. Sader and J. R. Friend. [**Note: Improved calibration of atomic force microscope cantilevers using multiple reference cantilevers**](http://scitation.aip.org/content/aip/journal/rsi/86/5/10.1063/1.4921192). Review of Scientific Instruments, 86(5), 2015.

1. A. G. McDonnell, T. C. Gopesh, J. Lo, M. O'Bryan, L. Y. Yeo, J. R. Friend, and R. Prabhakar. [**Motility induced changes in viscosity of suspensions of swimming microbes in extensional flows**](http://dx.doi.org/10.1039/C4SM02742F). Soft Matter, 11:4658-4668, 2015.

1. X. Zhang, J. Wang, L. Bao, E. Dietrich, R. C. A. van der Veen, S. Peng, J. Friend, H. J. W. Zandvliet, L. Yeo, and D. Lohse. [**Mixed mode of dissolving immersed nanodroplets at a solid-water interface**](http://dx.doi.org/10.1039/C4SM02397H). Soft Matter, , 2015.

1. J. Behrens, S. Langelier, A. R. Rezk, G. Lindner, L. Y. Yeo, and J. R. Friend. **Microscale anechoic architecture: acoustic diffusers for ultra low power microparticle separation via traveling surface acoustic waves**. Lab on a Chip, 15(1):43-46, 2015.

1. A. G. McDonnell, N. N. Jason, L. Yeo, J. R. Friend, W. Cheng, and P. Ranganathan. **Extensional viscosity of copper nanowire suspensions in an aqueous polymer solution**. Soft Matter, **11**:8076-8082, 2015.

1. M. Miansari, J. R. Friend, and L. Y. Yeo. [**Enhanced Ion Current Rectification in 2D Graphene-Based Nanofluidic Devices**](http://dx.doi.org/10.1002/advs.201500062). Advanced Science, 2(6):n/a--n/a, 2015.

1. O. Manor, A. R. Rezk, J. R. Friend, and L. Y. Yeo. [**Dynamics of liquid films exposed to high-frequency surface vibration**](http://link.aps.org/doi/10.1103/PhysRevE.91.053015). Phys. Rev. E, 91:053015, 2015.

1. A. R. Rezk, S. Walia, R. Ramanathan, H. Nili, J. Z. Ou, V. Bansal, J. R. Friend, M. Bhaskaran, L. Y. Yeo, and S. Sriram. [**Acoustic--Excitonic Coupling for Dynamic Photoluminescence Manipulation of Quasi-2D MoS2 Nanoflakes**](http://dx.doi.org/10.1002/adom.201500034). Advanced Optical Materials, 2015.

1. X. Zhang, J. Yao, M. Ali, J. Wei, H. Wang, L. Y. Yeo, J. R. Friend, and D. R. MacFarlane. **UV/ozone-assisted low temperature preparation of mesoporous TiO2 with tunable phase composition and enhanced solar light photocatalytic activity**. Journal of Materials Chemistry A, 2(44):18791-18795, 2014.

1. D. Yudistira, A. Boes, A. R. Rezk, L. Y. Yeo, J. R. Friend, and A. Mitchell. **UV Direct Write Metal Enhanced Redox (MER) Domain Engineering for Realization of Surface Acoustic Devices on Lithium Niobate**. Advanced Materials Interfaces, 1(1400006):1-7, 2014.

1. J. E. Sader, M. Yousefi, and J. Friend. **Uncertainty in Least-Squares Fits to the Thermal Noise Spectra of Nanomechanical Resonators with Applications to the Atomic Force Microscope**. Review of Scientific Instruments, 85(025104):1-5, 2014.

1. A. Boes, D. Yudistira, T. Crasto, H. Steigerwald, V. Sivan, T. Limboeck, J. Friend, S. Mailis, E. Soergel, and A. Mitchell. **Ultraviolet laser induced domain inversion on chromium coated lithium niobate crystals**. Optical Materials Express, 4(2):241-254, 2014.

1. A. M. Gracioso Martins, N. R. Glass, S. Harrison, A. R. Rezk, N. A. Porter, P. D. Carpenter, J. Du Plessis, J. R. Friend, and L. Y. Yeo. [**Toward Complete Miniaturisation of Flow Injection Analysis Systems: Microfluidic Enhancement of Chemiluminescent Detection**](http://dx.doi.org/10.1021/ac502878p). Analytical Chemistry, 86(21):10812-10819, 2014.

1. L. Y. Yeo and J. R. Friend. **Surface Acoustic Wave Microfluidics**. Annual Review of Fluid Mechanics, 46:379-406, 2014.

1. D. Yudistira, A. Boes, A. R. Rezk, L. Y. Yeo, J. R. Friend, and A. Mitchell. **Surface Acoustic Devices: UV Direct Write Metal Enhanced Redox (MER) Domain Engineering for Realization of Surface Acoustic Devices on Lithium Niobate (Adv. Mater. Interfaces 4/2014)**. Advanced Materials Interfaces, 1(1400006):1-7, 2014.

1. A. R. Rezk, J. R. Friend, and L. Y. Yeo. [**Simple, low cost MHz-order acoustomicrofluidics using aluminium foil electrodes**](http://dx.doi.org/10.1039/C4LC00182F). Lab Chip, 14:1802-1805, 2014.

1. X. Zhang, J. Yao, D. Li, X. Chen, H. Wang, L. Y. Yeo, and J. R. Friend. **Self-assembled highly crystalline TiO$_2$ mesostructures for sunlight-driven, pH-responsive photodegradation of dyes**. Materials Research Bulletin, 55:13-18, 2014.

1. J. Guo, J. L. W. Li, Y. Chen, L. Y. Yeo, J. R. Friend, and Y. Kang. **RF-activated standing surface acoustic wave for on-chip particle manipulation**. IEEE Transactions on Microwave Theory and Techniques, 62(9):1898-1904, 2014.

1. A. R. Rezk, L. Y. Yeo, and J. R. Friend. **Poloidal Flow and Toroidal Particle Ring Formation in a Sessile Drop Driven by Megahertz Order Vibration**. Langmuir, 30(37):11243--11247, 2014.

1. J. E. Sader and J. R. Friend. **Note: Calibration of atomic force microscope cantilevers using only their resonant frequency and quality factor**. Review of Scientific Instruments, 85(11):116101, 2014.

1. X. Zhang, W. Lu, J. Dai, L. Bourgeois, J. Yao, H. Wang, J. R. Friend, D. Zhao, and D. R. MacFarlane. **Nanofabrication of highly ordered, tunable metallic mesostructures via quasi-hard-templating of lyotropic liquid crystals**. Scientific Reports, 4(7420):1-5, 2014.

1. D. Yudistira, A. Boes, B. Djafari-Rouhani, Y. Pennec, L. Y. Yeo, A. Mitchell, and J. R. Friend. [**Monolithic Phononic Crystals with a Surface Acoustic Band Gap from Surface Phonon-Polariton Coupling**](http://link.aps.org/doi/10.1103/PhysRevLett.113.215503). Phys. Rev. Lett., 113:215503, 2014.

1. A. Al-Abboodi, R. Tjeung, P. M. Doran, L. Y. Yeo, J. Friend, Y. Chan, and P. Pui. **In Situ Generation of Tunable Porosity Gradients in Hydrogel-Based Scaffolds for Microfluidic Cell Culture**. Advanced Healthcare Materials, 3(10):1655-1670, 2014.

1. A. Qi, S. P. Hoo, J. Friend, L. Yeo, Z. Yue, and P. P. Chan. **Hydroxypropyl Cellulose Methacrylate as a Photo-Patternable and Biodegradable Hybrid Paper Substrate for Cell Culture and Other Bioapplications**. Advanced Healthcare Materials, 3(4):543--554, 2014.

1. M. Miansari, J. R. Friend, P. Banerjee, M. Majumder, and L. Y. Yeo. **Graphene-Based Planar Nanofluidic Rectifiers**. The Journal of Physical Chemistry C, 118(38):21856-21865, 2014.

1. M. B. Dentry, L. Y. Yeo, and J. R. Friend. [**Frequency effects on the scale and behavior of acoustic streaming**](http://link.aps.org/doi/10.1103/PhysRevE.89.013203). Phys. Rev. E, 89:013203, 2014.

1. A. Rajapaksa, A. Qi, L. Yeo, R. Coppel, and J. R. Friend. [**Enabling Practical Surface Acoustic Wave Nebulizer Drug Delivery via Amplitude Modulation**](http://dx.doi.org/10.1039/C4LC00232F). Lab Chip, 14(11):1858-1865, 2014.

1. A. E. Rajapaksa, J. J. Ho, A. Qi, R. Bischof, T.-H. Nguyen, M. Tate, D. Piedrafita, M. P. McIntosh, L. Y. Yeo, E. Meeusen, R. L. Coppel, and J. R. Friend. [**Effective pulmonary delivery of an aerosolized plasmid DNA vaccine via surface acoustic wave nebulization**](http://respiratory-research.com/content/15/1/60/abstract). Respiratory Research, 15(60):1-12, 2014.

1. A. Rezk, O. Manor, L. Y. Yeo, and J. R. Friend. **Double Flow Reversal in Thin Liquid Films Driven by MHz Order Surface Vibration**. Proceedings of the Royal Society A, 470(20130765)2014.

1. X. Zhang, Y. Zheng, D. G. McCulloch, L. Y. Yeo, J. R. Friend, and D. R. Macfarlane. **Controlled morphogenesis and self-assembly of bismutite nanocrystals into three-dimensional nanostructures and their applications**. Journal of Materials Chemistry A, 2(7):2275-2282, 2014.

1. K. Kulkarni, L. Y. Yeo, J. R. Friend, and P. Perlmutter. **An emerging reactor technology for chemical synthesis: Surface acoustic wave-assisted closed-vessel Suzuki coupling reactions**. Ultrasonics Sonochemistry, 21(4):1305-1309, 2014.

#### 2010-2014

1. J. Blamey, L. Y. Yeo, and J. R. Friend. Microscale capillary wave turbulence excited by high frequency vibration. *Langmuir*, **29**(11):3835-3845, 2013.

1. L. Bllaci, S. Kjellstrom, L. Eliasson, J. R. Friend, L. Y. Yeo, and S. Nilsson. Fast surface acoustic wave-matrix-assisted laser desorption ionization mass spectrometry of cell response from islets of langerhans. *Analytical Chemistry*, **85**(5):2623-2629, 2013.

1. M. Dentry, J. Friend, and L. Yeo. Continuous flow actuation between external reservoirs in small-scale devices driven by surface acoustic waves. *Lab on a Chip*, **14**:750-758, 2013.

1. T. Vuong, A. Qi, M. Muradoglu, L. Yeo, J. Friend, and T. W. Ng. Precise drop dispensation on superhydrophobic surfaces using acoustic nebulization. *Soft Matter*, **9**:3631-3639, 2013.

1. Y. Wang, J. Z. Ou, S. Balendhran, A. F. Chrimes, M. Mortazavi, D. D. Yao, M. R. Field, K. Latham, V. Bansal, J. R. Friend, S. Zhuiykov, N. V. Medhekar, M. S. Strano, and K. Kalantar-Zadeh. Electrochemical control of photoluminescence in two-dimensional mos 2 nanoflakes. *ACS Nano*, **7**(11):10083-10093, 2013.

1. D. Yudistira, A. Boes, D. Janner, V. Pruneri, J. Friend, and A. Mitchell. Polariton-based band gap and generation of surface acoustic waves in acoustic superlattice lithium niobate. *Journal of Applied Physics*, **114**(5)2013.

1. D. Chakraborty, J. R. Prakash, J. Friend, and L. Yeo. Fluid-structure interaction in deformable microchannels. *Physics of Fluids*, **24**(102002):1-21, 2012.

1. D. J. Collins, O. Manor, A. Winkler, H. Schmidt, J. Friend, and L. Yeo. Atomization off thin water films generated by high-frequency substrate wave vibrations. *Physical Review E*, **86**(056312)2012.

1. N. R. Glass, R. J. Shilton, P. Chan, J. R. Friend, and L. Y. Yeo. Miniaturized lab-on-a-disc (miniload). *Small*, **8**(12):1880-8, 2012.

1. S. Langelier, L. Yeo, and J. R. Friend. UV epoxy bonding for enhanced saw transmission and microscale acoustofluidic integration. *Lab on a Chip*, **12**:2970-2976, 2012.

1. O. Manor, L. Y. Yeo, and J. R. Friend. The appearance of boundary layers and drift flows due to high frequency surface waves. *Journal of Fluid Mechanics*, **707**:482-495, 2012.

1. A. Rezk, O. Manor, J. R. Friend, and L. Y. Yeo. Unique fingering instabilities and soliton-like wave propagation in thin acoustowetting films. *Nature Communications*, **3**(1167)2012.

1. A. Rezk, A. Qi, J. Friend, L. Yeo, and W.-H. Li. Uniform mixing in paper-based microfluidic systems using surface acoustic waves. *Lab on a Chip*, **12**:773-779, 2012.

1. J. E. Sader, J. A. Sanelli, B. D. Adamson, J. P. Monty, X. Wei, S. A. Crawford, J. R. Friend, I. Marusic, P. Mulvaney, and E. J. Bieske. Spring constant calibration of atomic force microscope cantilevers of arbitrary shape. *Review of Scientific Instruments*, **83**(103705):1-16, 2012.

1. R. J. Shilton, S. M. Langelier, J. R. Friend, and L. Y. Yeo. Surface acoustic wave solid-state rotational micromotor. *Applied Physics Letters*, **100**(3):033503, 2012.

1. M. Sridhar, D. K. Maurya, J. R. Friend, and L. Y. Yeo. Focused ion beam milling of microchannels in lithium niobate. *Biomicrofluidics*, **6**(012819)2012.

1. C.-H. Yun, L. Yeo, B. Yan, and J. Friend. Multi-degree-of-freedom ultrasonic micromotor for guidewire and catheter navigation: the NeuroGlide actuator. *Applied Physics Letters (and the May 1, 2012 issue of Virtual Journal of Biological Physics Research)*, **100**:164101, 2012.

1. P. K. Bhattacharjee, A. McDonnell, R. Prabhakar, L. Yeo, and J. Friend. Extensional flow of low viscosity fluids in capillary bridges formed by pulsed surface acoustic wave jetting. *New Journal of Physics*, **13**(023005)2011.

1. J. R. Friend and L. Y. Yeo. Microscale acoustofluidics: microfluidics driven via acoustics and ultrasonics. *Reviews of Modern Physics*, **83**:647-704, 2011.

1. N. R. Glass, R. Tjeung, P. Chan, L. Y. Yeo, and J. R. Friend. Organosilane deposition for microfluidic applications. *Biomicrofluidics*, **5**(3):036501, 2011. http://dx.doi.org/doi/10.1063/1.3625605

1. J. Ho, M. K. Tan, D. Go, L. Yeo, J. Friend, and H.-C. Chang. A paper-based microfluidic surface acoustic wave sample delivery and ionization source for rapid and sensitive ambient mass spectrometry. *Analytical Chemistry*, **83**(9):3260-6, 2011.

1. O. Manor, M. Dentry, J. R. Friend, and L. Y. Yeo. Substrate dependent drop deformation and wetting under high frequency vibration. *Soft Matter*, **7**:7976-7979, 2011.

1. A. Qi, P. Chan, J. Ho, A. Rajapaksa, J. Friend, and L. Yeo. Template-free synthesis and encapsulation technique for layer-by-layer polymer nanocarrier fabrication. *ACS Nano*, **5**(12):9583--9591, 2011.

1. R. Shilton, L. Y. Yeo, and J. Friend. Quantification of surface acoustic wave induced chaotic mixing-flows in microfluidic wells. *Sensors and Actuators B: Chemical*, **160**(1):1565-1572, 2011.

1. R. Shilton, N. Glass, P. Chan, L. Yeo, and J. Friend. Rotational microfluidic motor for on-chip microcentrifugation. *Applied Physics Letters (and in the July 1, 2011 issue of Virtual Journal of Biological Physics Research)*, **98**(254103)2011.

1. R. Tjeung, M. Hughes, L. Yeo, and J. Friend. Surface acoustic wave micromotor with arbitrary axis rotational capability. *Applied Physics Letters*, **99**:214101, 2011.

1. L. Y. Yeo, H.-C. Chang, P. P. Y. Chan, and J. R. Friend. Microfluidic devices for bioapplications. *Small*, **7**(1):12-48, 2011.

1. D. Chakrobarty, M. Bajaj, L. Yeo, J. Friend, M. Pasquali, and R. Jagadeeshan. Viscoelastic flow in a two-dimensional collapsible channel. *Journal of Non-Newtonian Fluid Mechanics*, **165**(19-20):1204-1218, 2010.

1. J. Friend and L. Yeo. Using laser doppler vibrometry to measure capillary surface waves on fluid-fluid interfaces. *Biomicrofluidics*, **4**(2):026501, 2010.

1. J. Friend and L. Yeo. Fabrication of microfluidics devices using polydimethylsiloxane (pdms). *Biomicrofluidics*, **4**(2):026502, 2010.

1. P. C. King, S. Zahiri, M. Jahedi, and J. Friend. Aluminium coating of lead zirconate titanate---a study of cold spray variables. *Surface \& Coatings Technology*, **205**(7):2016-2022, 2010.

1. K. Kulkarni, S. H. Ramarathinam, J. Friend, L. Yeo, A. Purcell, and P. Perlmutter. Rapid microscale in-gel processing and digestion of proteins using surface acoustic waves. *Lab on a Chip*, **10**(1518-1520)2010.

1. D. K.-C. Liu, J. Friend, and L. Yeo. A brief review of actuation at the micro-scale using electrostatics, electromagnetics and piezoelectric ultrasonics. *Acoustical Science and Technology*, **31**(2):115-123, 2010.

1. A. Qi, L. Yeo, J. Friend, and J. Ho. The extraction of liquid, protein molecules and yeast cells from paper through surface acoustic wave atomization. *Lab on a Chip*, **10**(4):470-476, 2010.

1. J. Qin, L. Yeo, and J. Friend. Micropiv and micromixing study of corona wind induced microcentrifugation flows in a cylindrical cavity. *Microfluidics and Nanofluidics*, **8**(2):231-241, 2010.

1. R. Raghavan, J. Friend, and L. Yeo. Particle concentration via acoustically driven microcentrifugation: microPIV flow visualization and numerical modelling studies. *Microfluidics and Nanofluidics*, **8**(1):73-84, 2010.

1. P. R. Rogers, J. R. Friend, and L. Y. Yeo. Exploitation of surface acoustic waves to drive size-dependent microparticle concentration within a droplet. *Lab on a Chip*, **10**(21):2979-2985, 2010.

1. M. K. Tan, J. R. Friend, O. K. Matar, and L. Y. Yeo. Capillary wave motion excited by high frequency surface acoustic waves. *Physics of Fluids*, **22**(11):112112, 2010. http://link.aip.org/link/?PHF/22/112112/1

1. M. K. Tan, L. Y. Yeo, and J. Friend. Unique flow transitions and particle collection switching phenomena in a microchannel induced by surface acoustic waves. *Applied Physics Letters*, **97**:234106, 2010.

1. B. Watson, J. Friend, and L. Yeo. Modelling and testing of a piezoelectric ultrasonic micro-motor suitable for in vivo micro-robotic applications. *Journal of Micromachining and Microengineering*, **20**(11):115018, 2010.

1. B. Watson, L. Yeo, and J. Friend. A study on axial and torsional resonant mode matching for a mechanical system with complex non-linear geometries. *Review of Scientific Instruments*, **81**:063901, 2010.

1. H. Yamamoto, K. Mori, K. Takemura, L. Yeo, J. Friend, S. Yokota, and K. Edamura. Numerical modeling of electro-conjugate fluid flows. *Sensors and Actuators A: Physical*, **161**:152-157, 2010.

1. L. Y. Yeo, J. R. Friend, M. P. McIntosh, E. N. Meeusen, and D. A. Morton. Ultrasonic nebulization platforms for pulmonary drug delivery. *Expert Opinion on Drug Delivery*, **7**(6):663-679, 2010.

1. C.-H. Yun, B. Watson, J. Friend, and L. Yeo. A piezoelectric ultrasonic linear micromotor using a slotted stator. *IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control*, **57**(8):1868-1874, 2010.

#### 1997-2009

1. M. Alvarez, L. Y. Yeo, J. R. Friend, and M. Jamriska. Rapid production of protein-loaded biodegradable microparticles using surface acoustic waves. *Biomicrofluidics*, **3**(1):014102, 2009. http://link.aip.org/link/?BMF/3/014102/1

1. M. Bok, H. Li, L. Yeo, and J. Friend. The dynamics of surface acoustic wave driven scaffold cell seeding. *Biotechnology and Bioengineering*, **103**(2):387-401, 2009.

1. R. P. Hodgson, M. Tan, L. Yeo, and J. Friend. Transmitting high power RF acoustic radiation via fluid couplants into superstrates for microfluidics. *Applied Physics Letters*, **94**(2):024102, 2009. http://link.aip.org/link/?APL/94/024102/1

1. T. F. Khoo, D. H. Dang, J. Friend, D. Oetomo, and L. Yeo. Triple degree-of-freedom piezoelectric ultrasonic micromotor via flexural-axial coupled vibration. *IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control*, **56**(8):1716-1724, 2009.

1. K. Kulkarni, J. Friend, L. Yeo, and P. Perlmutter. Surface acoustic wave assisted drop-scale synthetic chemistry. *Lab on a Chip*, **9**:754-5, 2009.

1. H. Li, A. Dasvarma, L. Yeo, J. Friend, and K. Traianedes. Effect of surface acoustic waves on the viability, proliferation and differentiation of primary osteoblast-like cells. *Biomicrofluidics*, **3**:034102, 2009.

1. D. K.-C. Liu, J. Friend, and L. Yeo. The axial-torsional vibration of pretwisted beams. *Journal of Sound and Vibration*, **321**(1-2):115-136, 2009.

1. K.-C. Liu, J. Friend, and L. Yeo. Rotating bouncing disks, tossing pizza dough, and the behavior of ultrasonic motors. *Physical Review E*, **80**(046201)2009.

1. K.-C. Liu, J. Friend, and L. Yeo. The behavior of bouncing disks and pizza tossing. *EPL*, **85**:60002, 2009.

1. A. Qi, J. Friend, L. Yeo, D. Morton, M. McIntosh, and L. Spiccia. Miniature inhalation therapy platform using surface acoustic wave microfluidic atomization. *Lab on a Chip*, **9**:2184-2193, 2009.

1. R. Raghavan, L. Yeo, J. Friend, K. Takemura, S. Yokota, and K. Edamura. Electrokinetic actuation of low conductivity dielectric liquids. *Sensors and Actuators B: Chemical*, **140**(1):287-294, 2009.

1. M. Tan, L.Yeo, and J. Friend. Rapid fluid flow and mixing induced in microchannels using surface acoustic waves. *EPL*, **87**(47003):1-6, 2009.

1. M. K. Tan, R. Tjeung, H. Ervin, L. Y. Yeo, and J. Friend. Double aperture focusing transducer for controlling microparticle motions in trapezoidal microchannels with surface acoustic waves. *Applied Physics Letters*, **95**(134101)2009.

1. M. K. Tan, J. Friend, and L. Y. Yeo. Interfacial jetting phenomena induced by focused surface vibrations. *Physical Review Letters*, **103**(2)2009.

1. B. Watson, J. Friend, and L. Yeo. Piezoelectric ultrasonic micro/milli-scale actuators. *Sensors and Actuators A: Physical*, **152**:219-233, 2009.

1. B. Watson, J. Friend, and L. Yeo. Piezoelectric ultrasonic resonant motor with stator diameter less than 250 microns: the Proteus motor. *Journal of Micromachining and Microengineering*, **19**:022001, 2009.

1. L. Y. Yeo, R. Prakash-Jagadeeshan, and J. Friend. Complex fluids and microfluidics workshop 2008 (CFMW08). *Applied Rheology*, **19**(1):44-46, 2009.

1. L. Y. Yeo and J. R. Friend. Ultrafast microfluidics using surface acoustic waves. *Biomicrofluidics*, **3**:012002, 2009.

1. M. Alvarez, J. Friend, and L. Yeo. Surface vibration induced spatial ordering of periodic polymer patterns on a substrate. *Langmuir*, **24**:10629-10632, 2008.

1. M. Alvarez, L. Yeo, and J. Friend. Rapid generation of protein aerosols and nanoparticles via SAW atomisation. *Nanotechnology*, **19**:455103, 2008.

1. J. Friend, L. Yeo, D. Arifin, and A. Mechler. Evaporative self-assembly assisted synthesis of polymeric nanoparticles by surface acoustic wave atomization. *Nanotechnology*, **19**:145301, 2008.

1. J. Friend, L. Yeo, and M. Hogg. Piezoelectric ultrasonic bidirectional linear actuator for micropositioning fulfilling Feynman's criteria. *Applied Physics Letters*, **92**(014107)2008.

1. C. Handapangoda, M. Premaratne, L. Yeo, and J. Friend. Modeling of light propagation through biological tissues: a novel approach. *Journal of selected topics in quantum electronics*, **14**(1):1-8, 2008.

1. H. Li, J. Friend, and L. Yeo. Colloidal island formation and erasure in a microfluidic system induced by surface acoustic wave radiation. *Physical Review Letters*, **101**:084502, 2008.

1. A. Qi, L. Yeo, and J. Friend. Interfacial destabilization and atomization driven by surface acoustic waves. *Physics of Fluids*, **20**:074103, 2008.

1. R. Shilton, M. K. Tan, L. Y. Yeo, and J. R. Friend. Particle concentration and mixing in microdrops driven by focused surface acoustic waves. *Journal of Applied Physics*, **104**:014910, 2008.

1. D. Wajchman, D. Liu, J. Friend, and L. Yeo. An ultrasonic piezoelectric motor utilising a non-circular cross sectioned twisted beam. *IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control*, **55**(4):832-840, 2008.

1. D. Arifin, L. Yeo, and J. Friend. Microfluidic blood plasma separation via bulk electrohydrodynamic flows. *Biomicrofluidics*, **1**:14103, 2007.

1. T. Ide, J. Friend, K. Nakamura, and S. Ueha. A non-contact linear bearing and actuator via ultrasonic levitation;. *Sensors and Actuators A: Physical*, **135**(2):740-747, 2007. http://www.sciencedirect.com/science/article/B6THG-4KYXHRR-1/2/4770082e6a4b8cc59cbcc338e8e5b001

1. P. C. King, S. H. Zahiri, M. Jahedi, and J. Friend. Cold spray electroding of piezoelectric ceramic. *Materials Forum*, **31**:116-119, 2007.

1. D. Koyama, T. Ide, J. Friend, K. Nakamura, and S. Ueha. An ultrasonically levitated noncontact stage using traveling vibrations on precision ceramic guide rails. *IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control*, **54**(3):597-604, 2007.

1. H. Li, J. Friend, and L. Yeo. Surface acoustic wave concentration of particle and bioparticle suspensions. *Biomedical Microdevices*, **28**:4098--4104, 2007. dx.doi.org/10.1007/s10544-007-9058-2

1. H. Li, J. R. Friend, and L. Y. Yeo. A scaffold cell seeding method driven by surface acoustic waves. *Biomaterials*, **9**(5):647-656, 2007. http://www.sciencedirect.com/science/article/B6TWB-4P2J38K-2/2/17ee17c3a4c13bb3d3cd1a469c765b9d

1. W. M. Tan, J. Friend, and L. Yeo. Direct visualization of surface acoustic waves along substrates using smoke particles. *Applied Physics Letters*, **91**:224101, 2007.

1. W. M. Tan, J. Friend, and L. Yeo. Microparticle collection and concentration via a miniature surface acoustic wave device. *Lab on a Chip*, **7**(5):618-625, 2007.

1. J. Friend, Y. Gouda, K. Nakamura, and S. Ueha. A 5-mm$^3$ bidirectional precision linear microactuator---the Baltan actuator. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **53**(6):1160-1168, June 2006.

1. L. Yeo and J. Friend. Electrospinning carbon nanotube polymer composite nanofibers. *Journal of Experimental Nanoscience*, **1**(2):177-209, June 2006.

1. G. Forde, J. Friend, and T. Williamson. Straightforward biodegradeable nanoparticle generation through MHz-order ultrasonic atomization. *Applied Physics Letters*, **89**:064105, 2006.

1. J. Friend, Y. Gouda, K. Nakamura, and S. Ueha. A simple bidirectional linear microactuator for nanopositioning - the "baltan" microactuator. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **53**(6):1160-1167, 2006.

1. L. Y. Yeo, J. R. Friend, and D. R. Arifin. Electric tempest in a teacup: the tea leaf analogy to microfluidic blood plasma separation. *Applied Physics Letters*, **89**(10):103516, 2006.

1. J. Friend, K. Nakamura, and S. Ueha. A traveling-wave modified ring linear piezoelectric microactuator with enclosed piezoelectric elements---the "scream'' actuator. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **52**(8):1343--1353, 2005. http://www.ieee-uffc.org/tr/covers.asp?view=2005

1. T. Hasegawa, J. Friend, K. Nakamura, and S. Ueha. Characteristics of ultrasonic suction pump without moving parts. *Japanese Journal of Applied Physics*, **44**:No. 6B, pp4658-4661, 2005.

1. T. Ide, J. Friend, K. Nakamura, and S. Ueha. A low-profile design for the nonconatct ultrasonically levitated stage. *Japanese Journal of Applied Physics*, **44**:No. 6B, pp4662-4665, 2005.

1. J. Saito, J. Friend, K. Nakamura, and S. Ueha. Resonant mode design for noncontact ultrasonic motor with levitated rotor. *Japanese Journal of Applied Physics*, **44**:No. 6B, pp4666-4668, 2005.

1. M. Tominaga, R. Kaminaga, J. Friend, K. Nakamura, and S. Ueha. An ultrasonic linear motor using ridge mode traveling waves. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **52**(10):1735-1742, 2005.

1. J. Friend, K. Nakamura, and S. Ueha. A piezoelectric micromotor using in-plane shearing of PZT elements. *IEEE/ASME Transactions on Mechatronics*, **9**(3):467-473, 2004.

1. J. Friend, K. Nakamura, and S. Ueha. A torsional transducer through in-plane shearing of paired planar piezoelectric elements. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **51**(7):871-878, 2004. http://www.ieee-uffc.org/archive/uffc/trans/Toc/papers/04/t0470871.pdf

1. J. Friend, K. Nakamura, and S. Ueha. Acoustic waveguides for actuators. *Japanese Journal of Applied Physics*, **43**(5B):3040-3044, 2004. http://jjap.ipap.jp/link?JJAP/43/3040/

1. J. Friend, A. Umeshima, T. Ishii, K. Nakamura, and S. Ueha. A piezoelectric linear actuator formed from a multitude of bimorphs. *Sensors and Actuators A*, **109**:241-252, 2004. http://www.sciencedirect.com/science?_ob=MImg&_imagekey=B6THG-4B724DV-5-37&_cdi=5282&_orig=search&_coverDate=01%2F01%2F2004&_sk=998909996&view=c&wchp=dGLbVtz-zSkzS&_acct=C000010218&_version=1&_userid=126251&md5=39d996f0403bf1c64f44a02344ab7e13&ie=f.pdf

1. J. Friend, J. Satonobu, K. Nakamura, S. Ueha, and D. Stutts. A single-element piezoelectric tuning fork linear actuator. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **50**(2):179-186, 2003. http://www.ieee-uffc.org/archive/uffc/trans/Toc/papers/03/t0320179.pdf

1. C.-H. Yun, S. Niwano, J. R. Friend, K. Nakamura, and S. Ueha. Support mechanism for the ball rotor in the three-degree-of-freedom ultrasonic motor. *Japanese Journal of Applied Physics*, **42**(Part 1, No. 5B):3000-3001, 2003. http://jjap.ipap.jp/link?JJAP/42/3000/

1. J. Satonobu and J. Friend. Numerical analysis of the symmetric hybrid transducer motor: comparison of characteristics calculated by transmission-line and lumped-element models. *Ultrasonics*, **39**:559-565, 2002.

1. J. Friend, E. Jamieson, M. Pennell, and W. Huebner. Ultrasonic characterization of poling in lead zirconate titanate ceramics. *Applied Physics Letters*, **79**:1513-1516, 2001.

1. J. Satonobu and J. Friend. Traveling-wave excitation in a flexural vibration ring by using a torsional-flexural composite transducer. *IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control*, **48**(4):1054-1059, 2001. http://www.ieee-uffc.org/archive/uffc/trans/toc/papers/01/t0141054.pdf

1. J. Satonobu and J. Friend. Numerical analysis of a symmetric hybrid transducer motor. *IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control*, **48**(6):1625-1631, 2001. http://www.ieee-uffc.org/archive/uffc/trans/Toc/papers/01/t0161625.pdf

1. J. Friend and D. Stutts. The dynamics of an annular piezoelectric motor stator. *Journal of Sound and Vibration*, **204**(3):231-247, 1997. http://www.sciencedirect.com/science?_ob=MImg&_imagekey=B6WM3-45KKRN5-78-1&_cdi=6923&_orig=search&_coverDate=07%2F17%2F1997&_sk=997959996&view=c&wchp=dGLbVtb-zSkWW&_acct=C000010218&_version=1&_userid=126251&md5=20788b109fc0f6c55716ebb642cc94fb&ie=f.pdf

Research details

Show me research related to ...

Making superfast recharging for 250 to 2000+ cycles in rechargeable lithium metal and lithium ion batteries practical by using surface acoustic wave devices

Lithium-ion battery application: A lithium-ion battery’s maximum charge rate and energy density are intrinsically limited by the ion diffusion rate in the electrolyte. Most research focuses on materials science solutions to this problem, with gradual improvement over the years. A mechanical solution is proposed to integrate an MHz-order frequency surface acoustic wave (SAW) device into an existing 1.8 Ah multilayered Li-ion pouch cell to enhance the ion diffusion rate and the overall battery performance. Both the charging rate and cycling lifetime are improved from SAW. At a 6C (10 min) charge and C/3 discharge rate, typical of electric vehicle applications, integrating SAW into the Li-ion cell doubles the energy density and maintains at least 72% of the battery’s initial capacity after 2000 cycles. Moreover, using SAW quantifiably reduces battery degradation in these conditions as deter- mined by optical imaging, scanning electron microscopy, X-ray diffraction, and neutron diffraction. The use of SAW appears to offer a method to avoid undesirable Li metal plating on the graphite anode during charging, and leads to a much longer battery lifetime and good charge capacity, all despite rapid charging.

Lithium metal battery application: Both powerful and unstable, practical lithium metal batteries have remained a difficult challenge for over 50 years. With severe ion depletion gradients in the electrolyte during charging, they rapidly develop porosity, dendrites, and dead Li that cause poor performance and, all too often, spectacular failure. Remarkably, incorporating a small, 100 MHz surface acoustic wave device (SAW) solves this problem. Providing acoustic streaming electrolyte flow during charging, the device enables dense Li plating and avoids porosity and dendrites. SAW-integrated Li cells can operate up to 6 mA cm−2 in a commer- cial carbonate-based electrolyte; omitting the SAW leads to short circuiting at 2 mA cm−2. The Li deposition is morphologically dendrite-free and close to theoretical density when cycling with the SAW. With a 245 μm thick Li anode in a full Li||LFP (LiFePO4) cell, introducing the SAW increases the uncycled

Li from 145 to 225 μm, decreasing Li consumption from 41% to only 8%. A closed-form model is provided to explain the phenomena and serve as a design tool for integrating this chemistry-agnostic approach into batteries whatever the chemistry within.

Practical handheld circuits for acoustofluidics

Acoustofluidics has promised to enable lab-on-a-chip and point-of-care devices in ways difficult to achieve using other methods. Piezoelectric ultrasonic transducers—as small as the chips they actuate— provide rapid fluid and suspended object transport. Acoustofluidic lab-on-chip devices offer a vast range of benefits in early disease identification and noninvasive drug delivery. However, their potential has long been undermined by the need for benchtop or rack-mount electronics. The piezoelectric ultrasonic transducers within require these equipment and thus acoustofluidic device implementation in a bedside setting has been limited. Here we detail a general process to enable the reader to produce battery or mains-powered microcircuits ideal for driving 1–300 MHz acoustic devices. We include the general design strategy for the circuit, the blocks that collectively define it, and suitable, specific choices for components to produce these blocks. We furthermore illustrate how to incorporate automated resonance finding and tracking, sensing and feedback, and built-in adjustability to accommodate devices' vastly different operating frequencies and powers in a single driver, including examples of fluid and particle manipulation typical of the needs in our discipline. With this in hand, the many groups active in lab-on-a-chip acoustofluidics can now finally deliver on the promise of handheld, point-of-care technologies.

Handheld centrifugation and separation

Asymmetric surface acoustic waves have been shown useful in separating particles and cells in many microfluidics designs, mostly notably sessile microdroplets. However, no one has successfully extracted target particles or cells for later use from such samples. We present a novel omnidirectional spiral surface acoustic wave (OSSAW) design that exploits a new cut of lithium niobate, 152 Y-rotated, to rapidly rotate a microliter sessile drop to ∼10 g, producing efficient multi-size particle separation. We further extract the separated particles for the first time, demonstrating the ability to target specific particles, for example, platelets from mouse blood for further integrated point-of-care diagnostics. Within ∼5 s of surface acoustic wave actuation, particles with diameter of 5 μm and 1 μm can be separated into two portions with a purity of 83% and 97%, respectively. Red blood cells and platelets within mouse blood are further demonstrated to be separated with a purity of 93% and 84%, respectively. These advancements potentially provide an effective platform for whole blood separation and point-of-care diagnostics without need for micro or nanoscale fluidic enclosures.

Acoustogeometric streaming

Past forms of acoustic streaming, named after their progenitors Eckart (1948), Schlichting (1932), and Rayleigh (1884), serve to describe fluid and particle transport phenomena from the macro to micro-scale. Governed by the fluid viscosity, traditional acoustic streaming arises from second-order nonlinear coupling between the fluid’s density and particle velocity, with the first-order acoustic wave time averaging to zero. We describe a form of acoustogeometric streaming that has a nonzero first-order contribution. Experimentally discovered in nanochannels of a height commensurate with the viscous penetration depth of the fluid in the channel, it arises from nonlinear interactions between the surrounding channel deformation and the leading order acoustic pressure field, generating flow pressures three orders of magnitude greater than any known acoustically mediated mechanism. It enables the propulsion of fluids against significant Laplace pressure, sufficient to produce 6 mm=s flow in a 130–150 nm tall nanoslit. We find quantitative agreement between theory and experiment across a variety of fluids and conditions, and identify the maximum flow rate with a channel height 1.59 times the viscous penetration depth.

Controlled droplet ejection

We study the nozzle-free ejection of liquid droplets at controlled angles from a sessile drop actuated from two, mutually opposed directions by focused surface acoustic waves with dissimilar parameters. Previous researchers assumed that jets formed in this way are limited by the Rayleigh angle. However, when we carefully account for surface tension in addition to the driving force, acoustic streaming, we find a quantitative model that reduces to the Rayleigh angle only when inertia is dominant, and suggests larger ejection angles are possible in many practical situations. We confirm this in demonstrating ejection at more than double the Rayleigh angle. Our model explains the effects of both fluid and input parameters on experiments with a range of liquids. We extract, from this model, a dimensionless number that serves as an analog for the typical Weber number for predicting single droplet events.

Mild traumatic brain injury in C. elegans via cavitation-free surface acoustic wave-driven ultrasonic irradiation

Micro/nano acoustofluidics: materials, phenomena, design, devices, and applications (review)

Improving and predicting fluid atomization via hysteresis-free thickness vibration of lithium niobate

Decontaminating surfaces with atomized disinfectants generated by a novel thickness-mode lithium niobate device

Driving morphological changes in magnetic nanoparticle structures through the application of acoustic waves and magnetic fields

From Acoustofluidics and Acoustic Microfluidics to Acoustic Nanofluidics

Cell agglomeration in the wells of a 24-well plate using acoustic streaming

Vibration-Induced Deagglomeration and Shear-Induced Alignment of Carbon Nanotubes in Air

Mixed mode of dissolving immersed nanodroplets at a solid-water interface

Calibration of atomic force microscope cantilevers using only their resonant frequency and quality factor

Acoustic–Excitonic Coupling for Dynamic Photoluminescence Manipulation of Quasi-2D MoS2 Nanoflakes

Our paper appears in Advanced Optical Materials. It shows that a surface acoustic wave (SAW) can effectively and reversibly modulate the photoluminescence in quasi-2D MoS2. This technique does not result in any structural or compositional change, which suggests the tremendous potential of integrating 2D materials on to SAW platforms for designing controllable, state-of-the-art optoelectronic systems. Thanks to Sharath Sriram’s leadership it made the cover of AOM.

Microscale anechoic architecture: acoustic diffusers for ultra low power microparticle separation via traveling surface acoustic waves

This paper presents a versatile and very low-power traveling SAW microfluidic sorting device able to displace and separate particles of different diameter in aqueous suspension; the travelling wave propagates through the fluid bulk and diffuses via a Schröder diffuser, adapted from its typical use in concert hall acoustics to be the smallest such diffuser to be suitable for microfluidics. The effective operating power range is two to three orders of magnitude less than current SAW devices, uniquely eliminating the need for amplifiers, and by using traveling waves to impart forces directly upon suspended microparticles, they can be separated by size. The manuscript appears in Lab on a Chip.

Extensional viscosity of copper nanowire suspensions in an aqueous polymer solution

This paper looks at the behavior of fluids that carry copper nanowires (left above) in suspension as an example of an extremely long and narrow nanoparticle. The purpose is to determine the fluid rheology so that such particles can be deposited on surfaces for a diverse range of applications, from solar cells to conductive electrodes as a replacement for the dwindling supply of indium.

Extensional viscosities from 3 mPa⋅s (1 mPa⋅s shear viscosity) to 37.2 Pa⋅s were observed via changes in the suspension concentration, thus capturing low viscosities that have been historically very challenging to measure (right above). These changes equate to an increase in the relative extensional viscosity of nearly 12,200 times at a volume fraction of just 0.027. Interactions between the wires and the necessary polymer additive strongly affect the rheology, with a reduction in the elasticity of the fluid as the buffer relaxation time falls from 819 to 59 μs above a critical particle concentration.

Toward Complete Miniaturisation of Flow Injection Analysis Systems: Microfluidic Enhancement of Chemiluminescent Detection

Conventional flow injection systems for aquatic environmental analysis typically comprise large laboratory benchscale equipment, which place considerable constraints for portable field use. Here, we demonstrate the use of an integrated acoustically driven microfluidic mixing scheme to enhance detection of a chemiluminescent species tris(2,2′-bipyridyl)dichlororuthenium(II) hexahydrate—a common chemiluminescent reagent widely used for the analysis of a wide range of compounds such as illicit drugs, pharmaceuticals, and pesticides.

Laser technique offers nano breakthrough

Using the new technique, RMIT University researchers have been able to more easily and efficiently produce surface acoustic waves on a piezoelectric chip - a type of crystal that generates these waves when certain electrical voltages are applied to it.

Surface acoustic waves are sound waves used in mobile and optical telecommunications and have ground-breaking potential applications in the fields of ultrasound technology, energy harvesting and sensors for harsh environments.

Effective pulmonary delivery of an aerosolized plasmid DNA vaccine via surface acoustic wave nebulization

We have demonstrated the ability—for the first time—to effectively transfect a large animal (sheep) with a naked plasmid DNA-based influenza vaccine (H1N1 Solomon Islands) using nebulisation of the pDNA and inhalation delivery. The work is published in Respiratory Research here and a PDF of the work is available here.

Pulmonary-delivered gene therapy promises to mitigate vaccine safety issues and reduce the need for needles and skilled personnel to use them. While plasmid DNA (pDNA) offers a rapid route to vaccine production without side effects or reliance on cold chain storage, its delivery to the lung has proved challenging. Conventional methods, including jet and ultrasonic nebulizers, fail to deliver large biomolecules like pDNA intact due to the shear stresses present during nebulization. In vitro structural analysis followed by in vivo protein expression studies served in assessing the integrity of the pDNA subjected to surface acoustic wave (SAW) nebulisation. In vivo immunization trials were then carried out in rats using SAW nebulized pDNA (influenza A, human hemagglutinin H1N1) condensate delivered via intratracheal instillation. Finally, in vivo pulmonary vaccinations using pDNA for influenza was nebulised and delivered via respirator to sheep.

The SAW nebulizer was effective at generating pDNA aerosols with sizes optimal for deep-lung delivery. Successful gene expression was observed in mouse lung epithelial cells, when SAW-nebulized pDNA was delivered to a male Swiss mouse via intratracheal instillation. Effective systemic and mucosal antibody responses was found in rats via post-nebulized, condensed fluid instillation. Significantly, we demonstrated the suitability of the SAW nebulizer to administer unprotected pDNA encoding an influenza A virus surface glycoprotein to respirated sheep via aerosolized inhalation.

Self-assembled highly crystalline TiO2 mesostructures for sunlight-driven, pH-responsive photodegradation of dyes

Dyes are a routine contaminant of water, breaking down slowly, if at all, and presenting substantial environmental risks for a rapidly dwindling resource: water. We have now a route to breaking down such dyes using nanostructured titania, that, upon exposure to sunlight, effectively break down the dyes as reported in the Materials Research Bulletin.

The development of new strategies and photocatalytic materials for practical environmental solutions remains a great challenge, particularly due to the large energy demands associated with various remediation processes. In this paper, we report the fabrication of self-assembled ordered mesoporous TiO2 with highly crystalline anatase structures as well as high surface area, and characterize their photocatalytic performance on the degradation of three typical dyes, including anionic methyl orange, cationic methylene blue, and neutral rhodamine B driven merely by sunlight. The results show that the dye photodegradation strongly depends on the charging state of both mesoporous TiO2 surface and dyes, which can be adjusted by the pH value of the solutions. Such charge-dependent photocatalytic functionality of mesoporous TiO2 can thus be exploited for highly efficient and selective dye photodegradation.

Simple and Low Cost Acoustomicrofluidics Using Aluminium Foil

While some have adopted our SAW microfluidics devices and are researching that, we’ve found an entirely easier way to accomplish the same outcomes: using simple aluminum foil electrodes, published in Lab on a Chip here, and available for download here. We’ve also put a patent out this and related technologies fro commercialisation.

We show that it is possible to circumvent the necessity for costly and complex cleanroom fabrication procedures required for the production of MHz-order acoustically- driven microfluidic platforms through the use of electrode strips simply cut from kitchen aluminium foil. By completely removing the high device production costs and addressing issues associated with the reliability of complicated electrode technology, this exceptionally simple and low-cost acoustofluidic platform, on which we demonstrate rapid and efficient fluid transport and manipulation, microcentrifugation, and, remarkably, even nebulisation, in both sessile drops as well as paper-based substrates, is therefore a significant step closer towards commercially-viable consumer diagnostic devices, especially for use in the developing world.

Enabling Practical Surface Acoustic Wave Nebulizer Drug Delivery via Amplitude Modulation

A practical, commercially viable microfluidic device relies upon the miniaturization and integration of all its components—including pumps, circuitry, and power supply—onto a chip-based platform. Surface acoustic waves (SAW) have become popular in microfluidic manipulation, in solving the problems of microfluidic manipulation, but practical applications employing SAW still require more power than available via a battery. Introducing amplitude modulation at 0.5–40 kHz in SAW nebulization, which requires the highest energy input levels of all known SAW microfluidic processes, halves the power required to 1.5 W even while including the power in the sidebands, suitable for small lithium ion batteries, and maintains the nebulization rate, size, and size distributions vital to drug inhalation therapeutics. This simple yet effective means to enable an integrated SAW microfluidics device for nebulization exploits the relatively slow hydrodynamics and is furthermore shown to deliver shear-sensitive biomolecules—plasmid DNA and antibodies as exemplars of future pulmonary gene and vaccination therapies—undamaged in the nebulized mist. Altogether, the approach demonstrates a means to offer truly micro-scale microfluidics devices in a handheld, battery powered SAW nebulization device.

An emerging reactor technology for chemical synthesis: Surface acoustic wave-assisted closed-vessel Suzuki coupling reactions

In this paper we demonstrate the use of an energy-efficient surface acoustic wave (SAW) device for driving closed-vessel SAW-assisted (CVSAW), ligand-free Suzuki couplings in aqueous media. The reactions were carried out on a µmolar scale with low to ultra-low catalyst loadings. The reactions were driven by heating resulting from the penetration of acoustic energy derived from RF Raleigh waves generated by a piezoelectric chip via a renewable fluid coupling layer. The yields were uniformly high and the reactions could be executed without added ligand and in water. In terms of energy density this new technology was determined to be roughly as efficient as microwaves and superior to ultrasound.

Uncertainty in least-squares fits to the thermal noise spectra of nanomechanical resonators with applications to the atomic force microscope

Thermal noise spectra of nanomechanical resonators are used widely to characterize their physical properties. These spectra typically exhibit a Lorentzian response, with additional white noise due to extraneous processes. Least-squares fits of these measurements enable extraction of key parameters of the resonator, including its resonant frequency, quality factor, and stiffness. Here, we present general formulas for the uncertainties in these fit parameters due to sampling noise inherent in all thermal noise spectra. Good agreement with Monte Carlo simulation of synthetic data and measurements of an Atomic Force Microscope (AFM) cantilever is demonstrated. These formulas enable robust interpretation of thermal noise spectra measurements commonly performed in the AFM and adaptive control of fitting procedures with specified tolerances.

Frequency effects on the scale and behavior of acoustic streaming

From Physical Review E, indicating what happens to acoustic streaming as you continue to increase in frequency from low MHz to GHz order.

Acoustic streaming underpins an exciting range of fluid manipulation phenomena of rapidly growing significance in microfluidics, where the streaming often assumes the form of a steady, laminar jet emanating from the device surface, driven by the attenuation of acoustic energy within the beam of sound propagating through the liquid. The frequencies used to drive such phenomena are often chosen ad hoc to accommodate fabrication and material issues. In this work, we seek a better understanding of the effects of sound frequency and power on acoustic streaming. We present and, using surface acoustic waves, experimentally verify a laminar jet model that is based on the turbulent jet model of Lighthill, which is appropriate for acoustic streaming seen at micro- to nanoscales, between 20 and 936 MHz and over a broad range of input power. Our model eliminates the critically problematic acoustic source singularity present in Lighthill’s model, replacing it with a finite emission area and enabling determination of the streaming velocity close to the source, predicting (as shown in figure above) a transition from laminar jetting to turbulent jetting in a small water drop.

Controlled morphogenesis and self-assembly of bismutite nanocrystals into three-dimensional nanostructures and their applications

From the Journal of Materials Chemistry A, showing the complex micro/nanostructure formed by Na3C6H5O7 at different pH values.

It is now possible to control the morphogenesis and self-assembly of bismutite nanocrystals with fully tunable morphologies from square plates, octagonal sheets, and round disks into three-dimensional hierarchical nanostructures. The results show that the nucleation, growth and self-assembly of bismutite nanocrystals strongly depend on the synergistic effect between hydroxide and citrate ions. The three-dimensional hierarchical nanostructures are formed through an oriented-attachment of bismutite nanocrystals along the 〈001〉 directions. The bismutite hierarchical nanostructures can be utilized for efficient and selective adsorption and separation. A novel surface-enhanced Raman spectroscopy platform based on a bismutite/gold nanoparticles core–shell structure has been developed for ultrasensitive detection of aromatic molecules with a detection limit down to 1 nM.

Ultraviolet laser-induced domain inversion on chromium-coated lithium niobate crystals

Direct UV laser writing on chromium coated lithium niobate (LiNbO3) crystals is found to produce spontaneous domain inversion associated with the exposed UV laser tracks. Experimental evidence suggests that this effect is attributed to local out-diffusion of oxygen, reducing the LiNbO3 crystal surface due to the presence of chromium. The thin chromium film becomes hot and reactive after absorbing the UV laser radiation thus acting as an oxygen getter. This very efficient process enables the inversion of domains at lower intensities as compared to other direct laser based poling methods practically eliminating the deleterious surface damage induced by the direct absorption of the UV laser radiation by the crystal. Furthermore, the versatility of this domain fabrication method, is demonstrated by the production of inverted domain structures on Z-, Y- and 128 deg YX-cut substrates.

Continuous flow actuation between external reservoirs in small-scale devices driven by surface acoustic waves

We have designed and characterized a surface acoustic wave (SAW) fluid actuation platform that significantly improves the transmission of sound energy from the SAW device into the fluid in order to obtain enhanced performance. This is in distinct contrast to previous SAW microfluidic devices where the SAW substrate is simply interfaced with a microchannel without due consideration given to the direction at which the sound energy is transmitted into the fluid, thus resulting in considerable reflective and dissipative losses due to reflection and absorption at the channel walls. For the first time, we therefore demonstrate the ability for continuous fluid transfer between independent reservoirs driven by the SAW in a miniature device, and report the associated pressure–flow rate relationship, in which a maximum flowrate of 100 μl/min and pressure of 15 Pa was obtained. The pumping efficiency is observed to increase with input power, and, at peak performance, offers an order-of-magnitude improvement over that of existing SAW micropumps that have been reported to date.

Hydroxypropyl Cellulose Methacrylate as a Photo‐Patternable and Biodegradable Hybrid Paper Substrate for Cell Culture and Other Bioapplications

In addition to the choice of appropriate material properties of the tissue construct to be used, such as its biocompatibility, biodegradability, cytocompatibility, and mechanical rigidity, the ability to incorporate microarchitectural patterns in the construct to mimic that found in the cellular microenvironment is an important consideration in tissue engineering and regenerative medicine. Both these issues are addressed by demonstrating a method for preparing biodegradable and photo-patternable constructs, where modified cellulose is cross-linked to form an insoluble structure in an aqueous environment. Specifically, hydroxypropyl cellulose (HPC) is rendered photocrosslinkable by grafting with methylacrylic anhydride, whose linkages also render the cross-linked construct hydrolytically degradable. The HPC is then cross-linked via a photolithography-based fabrication process. The feasibility of functionalizing these HPC structures with biochemical cues is verified post-fabrication, and shown to facilitate the adhesion of mesenchymal progenitor cells. The HPC constructs are shown to be biocompatible and hydrolytically degradable, thus enabling cell proliferation and cell migration, and therefore constituting an ideal candidate for long-term cell culture and implantable tissue scaffold applications. In addition, the potential of the HPC structure is demonstrated as an alternative substrate to paper microfluidic diagnostic devices for protein and cell assays.

Polariton-based band gap and generation of surface acoustic waves in acoustic superlattice lithium niobate

We report the presence of surface acoustic wave (SAW, a) band gap (b) on acoustic superlattice (ASL) in a single-crystal lithium niobate structure. The calculated band gap appears at a frequency twice the value expected from purely acoustic Bragg scattering. We have identified the band gap as originating from a polariton-based mechanism due to the coupling between the electromagnetic wave and the surface vibrations. We have examined the influence of the band gap on SAW generation with the ASL and have shown that the © calculated frequency resonance of the SAW lies in the vicinity of the upper stop-band edges. This results in the localization of the SAW in the ASL. Experimental confirmation is achieved through direct measurement of the SAW displacement by laser vibrometry on an actual ASL SAW transducer.

Microscale Capillary Wave Turbulence Excited by High Frequency Vibration

Low frequency (O(10 Hz–10 kHz)) vibration excitation of capillary waves has been extensively studied for nearly two centuries. Such waves appear at the excitation frequency or at rational multiples of the excitation frequency through nonlinear coupling due to the finite displacement of the wave, most often at one-half the excitation frequency in so-called Faraday waves and twice this frequency in superharmonic waves. Less understood, however, are the dynamics of capillary waves driven by high frequency vibration (>O(100 kHz)) and small interface length scales, an arrangement ideal for a broad variety of applications, from nebulisers for pulmonary drug delivery to complex nanoparticle synthesis. In the few studies conducted to date, a marked departure from the predictions of classical Faraday wave theory has been shown, with the appearance of broadband capillary wave generation from 100 Hz to the excitation frequency and beyond, but there has not yet been a clear explanation. We show that weak wave turbulence is the dominant mechanism in the behavior of the system, evident from wave height frequency spectra that closely follows the Rayleigh-Jeans spectral response η ∼ ω^(−17/12) as a consequence of a period-halving, weakly turbulent cascade that appears within a 1 mm water drop whether driven by thickness-mode or surface acoustic Rayleigh wave excitation. However, such a cascade is one-way, from low to high frequencies. The mechanism of exciting the cascade with high frequency acoustic waves is an acoustic streaming-driven turbulent jet in the fluid bulk, driving the fundamental capillary wave resonance through the well-known coupling between bulk flow and surface waves. Unlike capillary waves, turbulent acoustic streaming can exhibit subharmonic cascades from high to low frequencies; here it appears from the excitation frequency all the way to the fundamental modes of the capillary wave some four orders of magnitude in frequency less than the excitation frequency, enabling the capillary weakly turbulent wave cascade to form from the fundamental capillary wave upwards.

Unique fingering instabilities and soliton-like wave propagation in thin acoustowetting films

Acoustic–fluid interactions not only has had a long history but has recently experienced renewed scrutiny because of their vast potential for microscale fluid and particle manipula- tion. Here we unravel a fascinating and anomalous ensemble of dynamic ‘acoustowetting’ phenomena in which a thin film drawn from a sessile drop first spreads in opposition to the acoustic wave propagation direction. The advancing film front then exhibits fingering instabilities akin to classical viscous fingering, but arising through a different and novel mechanism: transverse Fresnel diffraction of the underlying acoustic wave. Peculiar ‘soliton-like’ wave pulses are observed to grow above these fingers, which, on reaching a critical size, translate away along the wave propagation direction. By elucidating the complex hydrodynamics underpinning the spreading, and associated flow reversal and instability phenomena, we offer insight into the possibility of acoustically controlling fast and uniform film spreading, constituting a flexible and powerful alternative for microfluidic transport.

Figure: (a) The setup with oil drop, (b) top view with fluorescence, © exposure to SAW draws a film toward the acoustic source, (d) the leading edge of the film deepens and forms rapidly moving drops away from the source, and (e) this develops into a broadly occurring phenomenon that maintains mass conservation.

Precise drop dispensation on superhydrophobic surfaces using acoustic nebulization

The adhesion forces of liquid drops on superhydrophobic surfaces are typically in the nano-Newton range which presents problems in their dispensation from pipettes. Furthermore, since the liquid adheres more strongly to the pipette tip, some portion of the liquid will tend to remain on the tip, causing inaccuracy in the volume dispensed. We advance a novel approach here, in which the spray from an acoustic nebulizer is sent to a superhydrophobic receptacle and the volume ascertained precisely using a weighing scale. The volume dispensed was found to vary linearly with the operation time of the nebulizer.

Fast Surface Acoustic Wave-Matrix-Assisted Laser Desorption Ionization Mass Spectrometry of Cell Response from Islets of Langerhans