MADLab is moving

Our group is taking up residence in Jubel Hall on the campus of Washington University in St. Louis, with a new 1300 sq ft laboratory, new equipment and facilities, and a renewed emphasis on research output in acoustofluidics and related research areas.

We will have openings for post docs, particularly those skilled in analytical efforts, and PhD students interested in our research area.

Our website at WashU is here.

research

From acoustofluidics to devices

Our group creates and employs novel engineering and fabrication approaches to overcome longstanding problems, mostly in medicine. We use acoustofluidics, micro/nanofabrication methods, and our discoveries in new fundamental physical phenomena to make way towards applications. Please see below about our recent research, and our team, facilities, funding, and teaching activities. We're happy to collaborate with academic and industrial colleagues, and are fortunate to have among the best medical, fabrication, and testing facilities in the world. We also host faculty, students, and industry employees.

Highlights

Uncloggable ventriculoperitoneal shunt system for hydrocephalus via an integrated soft robotic device: the CLEARS device

Ventriculoperitoneal (VP) shunt obstruction, often caused by protein and fat accumulation at the ventricular catheter ports, impedes cerebrospinal fluid (CSF) outflow, increases intracranial pressure (ICP), and leads to hydrocephalus. Current treatments require invasive shunt removal, reimplantation, or retrograde flush cleansing. We present a next-generation VP shunt system that actively removes blockages via external actuation. Our system, called CLogging Elimination ActuatoR Silicone (CLEARS), integrates a soft, expandable silicone tube within the catheter lumen. This soft robotic insert, capable of 900% strain, can inflate to dislodge blockages and then deflate to restore flow.

Fluid flow measurements in nanoslits using holographic microscopy

Measuring flow in nanofluidic systems is difficult, especially at the high speeds induced by acoustic streaming and acoustogeometric streaming. We describe an approach to achieve this result using digital holographic transmission microscopy, showing the ability to track fluid interfaces moving at 12 cm/s from acoustogeometric streaming in a 25 nm channel. https://pubs.acs.org/doi/10.1021/acs.analchem.4c01615?ref=pdf

Surface acoustic wave-driven enhancement of enzyme-linked immunosorbent assays: ELISAW

Enzyme-linked immunosorbent assays (ELISAs) are widely used in biology and clinical diagnosis. Relying on antigen−antibody interaction through diffusion, the standard ELISA protocol can be time-consuming, preventing its use in rapid diagnostics. We present a time-saving and more sensitive ELISA without changing the standard setup and protocol, using surface acoustic waves (SAWs) to enhance performance. Each step of the assay, from the initial antibody binding onto the walls of the well plate to the target analyte molecules’ binding for detection—except, notably, for the blocking step—is improved principally via acoustic streaming-driven advection. https://pubs.acs.org/doi/10.1021/acs.analchem.4c01615?ref=pdf

Application of statistical analysis and machine learning to identify infants' abnormal suckling behavior

We demonstrate using a simple instrumented pacifier on 91 infants with statistical analysis and machine learning that normal and abnormal infant suckling can be identified and used in determining if surgical intervention is a necessary solution to resolve infant feeding difficulties. https://pubmed.ncbi.nlm.nih.gov/38765888/ This has resulted in the founding of our startup company, Latchability Inc.

Recent selected publications

1. Y. C. Yun, D. Santiago-Dieppa, M. Li, A. Vasan, A. Khalessi, and J. Friend. Uncloggable ventriculoperitoneal shunt system for hydrocephalus via an integrated soft robotic device: clears device. *Biomedical Microdevices*, **27**(4):1–9, 2025.

1. S. Yu, J. Orosco, and J. Friend. Fluid flow measurements in nanoslits using holographic microscopy. *Langmuir*, **41**(9):5860-5869, 2025.

1. X. Li, J. Chen, Y. Yang, H. Cai, Q. Huang, Z. Ao, Y. Xing, K. Li, K. Yang, A. Wallace, J. Friend, L. P. Lee, and F. Guo. Extracellular vesicle-based point-of-care testing for diagnosis and monitoring of Alzheimer's disease. *Microsystems \& Nanoengineering (Nature)*, **Accepted 11 December**2024.

1. W. Connacher, J. Orosco, O. Schmidt, and J. Friend. Direct observation of small scale capillary wave turbulence using high speed digital holographic microscopy. *Frontiers in Acoustics*, (1512579), 2024.

1. P. Truong, E. H. Walsh, V. P. Scott, M. Leff, A. Chen, and J. Friend. Application of statistical analysis and machine learning to identify infants' abnormal suckling behavior. *{IEEE} Journal of Translational Engineering in Health and Medicine*, **12**:435-447, 2024.

1. D. Santiago-Dieppa and J. Friend. Endovascular microrobotics for neurointervention. *Annual Review of Control, Robotics, and Autonomous Systems*, **7**(385-408)2024. https://doi.org/10.1146/annurev-control-060523-010720

1. L. Zhang, S. Zhang, C. Floer, S. Kantubuktha, M. Velasco, and J. Friend. Surface acoustic wave-driven enhancement of enzyme-linked immunosorbent assays: ELISAW. *Analytical Chemistry (ACS Editors' Choice)*, **96**(23):9676-9683, 2024.

1. A. Vasan, U. Magaram, J. Patel, J. Friend, and S. Chalasani. Integrating ultrasound-induced neural activity modulation with fiber photometry. *Frontiers in Acoustics*, **1** 2023.

1. O. Dubrovski, J. Friend, and O. Manor. Theory of acoustic streaming for arbitrary Reynolds number flow. *Journal of Fluid Mechanics*, **975***(A4):1-22, 2023.

1. S. C. Johns, P. Gupta, Y.-H. Lee, J. Friend, and M. M. Fuster. Glycocalyx transduces membrane leak in brain tumor cells exposed to sharp magnetic pulsing. *Biophysical Journal*, **122**:4425-4439, 2023

1. .J. Friend. Acoustofluidics. *Frontiers in Acoustics*, **1** 2023.

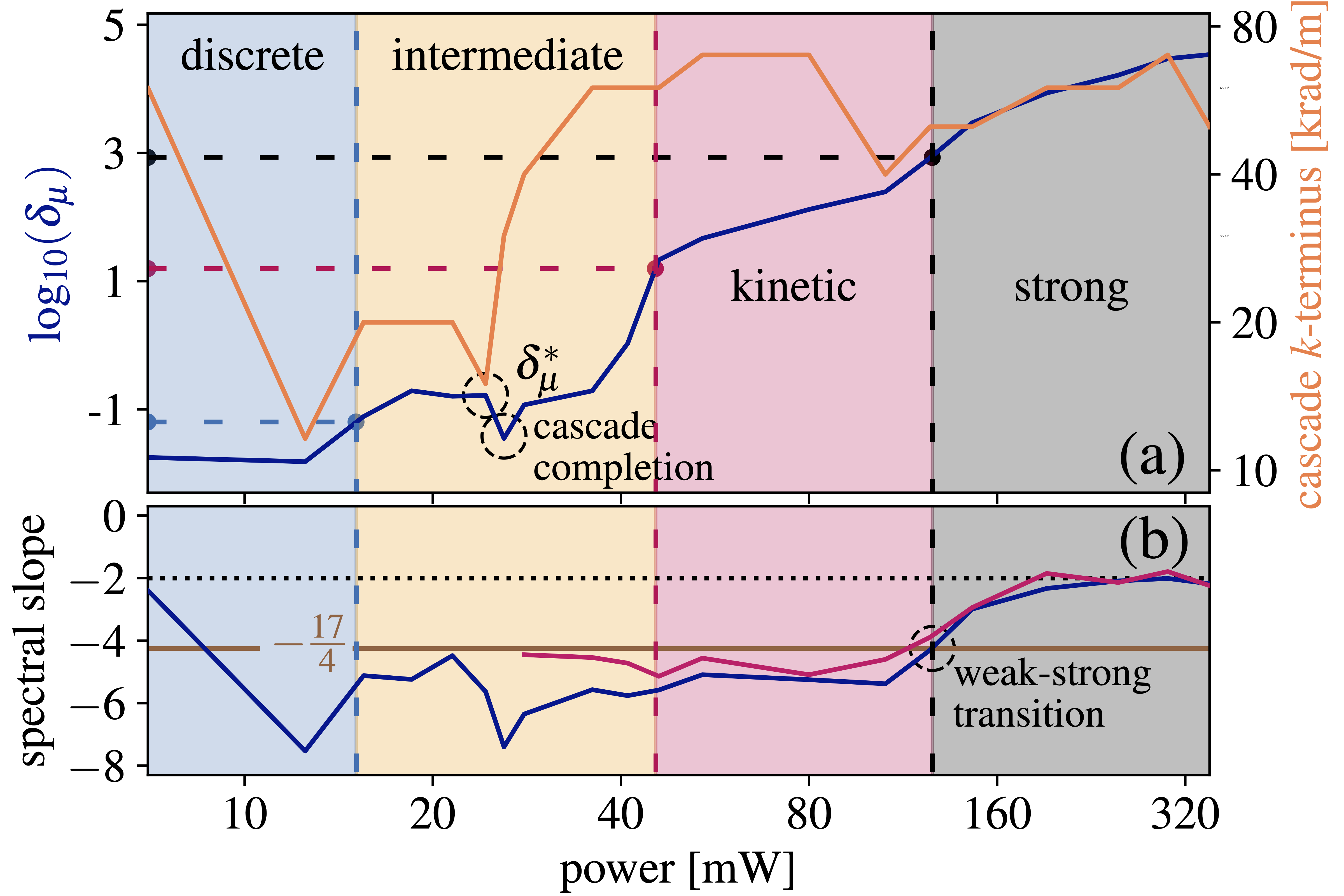

1. J. Orosco and J. Friend. Identification of weakly to strongly-turbulent three-wave processes in a micro-scale system. *Chaos, Solitons & Fractals*, **172**(113615):1-7, 2023. https://authors.elsevier.com/sd/article/S0960-0779(23)00516-7

1. S. Zhang, J. Orosco, and J. Friend. Onset of visible capillary waves from high-frequency acoustic excitation. *Langmuir*, **39**(10):3699-3709, 2023. https://doi.org/10.1002/smll.202204288

1. A. Horesh, W. Connacher, and J. Friend. Acoustothermal phase change and acoustically driven atomization for cold liquid microthrusters. *Applied Physics Letters*, **122**(014104):1-7, 2023. https://doi.org/10.1063/5.0131467

1. Y. Zhou, N. Zhang, D. J. Bisharat, R. J. Davis, Z. Zhang, J. Friend, P. R. Bandaru, and D. F. Sievenpiper. On-chip unidirectional waveguiding for surface acoustic waves along a defect line in a triangular lattice. *Physical Review Applied*, **19**(2)2023. https://doi.org/10.1103%2Fphysrevapplied.19.024053

Identification of strong turbulence in acoustically-driven capillary waves and the mechanism responsible for them

In a series of papers we show that capillary waves generated upon the surface of fluid interfaces by ~7 MHz to 50 MHz acoustic waves is strongly turbulent, generated by the formation and subsequent changes of the acoustic standing wave in the fluid cavity on the hydrodynamic (slow) time scale, and that with certain power levels weak, intermediate, discrete, and strong wave turbulence appears. Atomization appears at a power level well beyond what is needed to produce strong turbulence, indicating that Faraday waves and parametric turbulence are not responsible for atomization. https://doi.org/10.1016/j.chaos.2023.113615

https://doi.org/10.1021/acs.langmuir.2c03403

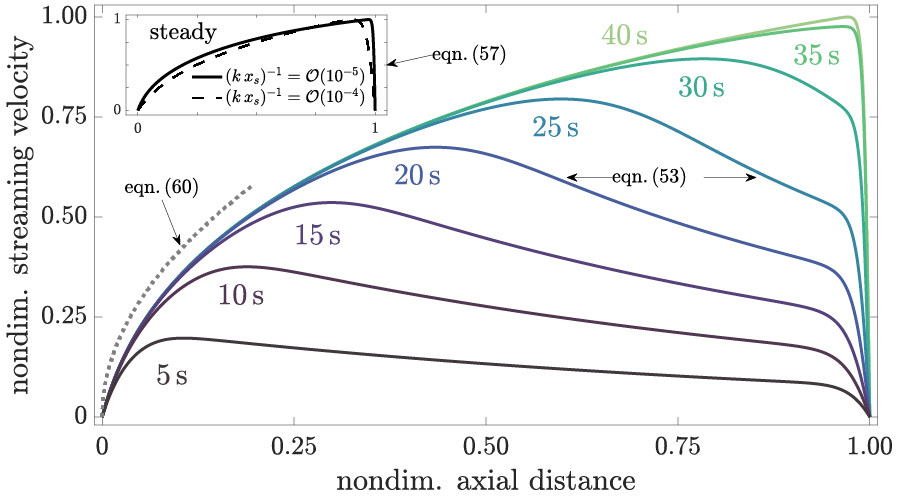

Explaining acoustic streaming

Acoustic streaming is a key phenomena underpinning many of the research works pursued by this laboratory and by other groups interested in ways to drive fluids in microfluidic and nanofluidic systems: Acoustofluidics. Following on from our earlier discovery of acoustogeometric streaming (PRL 126 164502 (2021)) which is uniquely powerful at the nano-scale, we examine the analysis of acoustic streaming in two new papers, one showing how to analyze transient acoustic streaming properly (Phys Rev E 106 045101 2022), and another showing how to handle traditional steady-state acoustic streaming (JFM 975(A4) 2023). These replace classic analysis methods from Nyborg, Rayleigh, Eckart, and Westervelt.

Rapidly changing magnetic fields induces plasma leaks in cancerous brain tumor cells but not healthy cells

The glycocalyx of lung cancer cells might play a role in mediating plasma membrane leak by low-frequency pulsed magnetic fields (Lf-PMF) generated on a low-energy solenoid platform. Appearing in the Biophysical Journal (Cell): https://doi.org/10.1016/j.bpj.2023.10.020

The mechanisms of sonogenetics

In a recent series of papers produced as a collaboration with the Salk Institute of Biological Sciences, we have made advances toward understanding the reasons behind ultrasound’s interactions with neurons (Advanced Science 2021), microscale devices to provide ultrasound transmission into the brains of mice (Advanced NanoBioMed Research 2022), and the use of hsTRPA1 as a mechanosensitive ion channel suitable for this purpose (Nature Communications 2022). This work is now featured in a new company, SonoBac.

Making lithium ion and metal rechargeable batteries fast-chargeable for 250 to 2000 cycles

A new method to enable ten-minute 0 to 100% charging of lithium metal batteries to over 250 cycles. Also works for lithium ion batteries,making it possible to recharge 0 to 100% in 10 min for over 2000 cycles. Now featured in a new company, Sonocharge with a recent publication.

Acoustogeometric streaming

Acoustogeometric streaming is a new form of acoustic streaming that couples the deformation of the surrounding channel with the acoustic wave to produce high pressures and rapid fluid flow, especially effective at the nano scale in manipulating, splitting, merging, and mixing 200 fL droplets.

Our research group (Current & Former)

Current members

Alexi Gill

Alexi is a M.S. student in the Mechanical and Aerospace Engineering department at UC San Diego, and joined the MADLab in the Fall of 2024. He completed his BS degree at UCLA in 2024, where he conducted research on rapid prototyping laser microfabrication and single-cell trapping with air-cavity based acoustophoretic trapping devices. He also has experience in the medical device industry, where he worked on NiTi mesh material characterization, design validation testing, and post-testing failure analysis for an endovascular mechanical thrombectomy catheter device. His research interests include acoustophoresis for biofabrication and the integration of acoustofluidics into implantable medical devices.

Yan Wan

Yan is a PhD student in the Materials Science program at UCSD. Yan joined the MADLab as a PhD student in the University of California, San Diego Materials Program Science and Engineering program in February 2025. Before joining the MADLab, he earned a bachelor’s degree in Polymer Materials and Engineering from Beijing University of Chemical Technology and a master’s degree in Chemical and Biomolecular Engineering from Johns Hopkins University. He had a background in microfabrication, drug delivery devices, polymer materials, and scientific illustration. He is currently working on designing and optimizing SAW devices for cell detachment.He is moving with MADLab to WashU.

Spencer Martin

Spencer is a master's student in the MADlab, starting in Fall 2024. He is interested in all things related to the medical applications of engineering and has completed a Bachelor's degree in Mechanical Engineering with a specialization in Controls and Robotics at UCSD. He is pursuing a degree in Mechanical Engineering with an emphasis on fluidics as well as controls. In his free time, he enjoys playing instruments, board games, and card games as well as reading.

Howard Tsang

Howard (Howie) Tsang is a PhD student in the Department of Mechanical and Aerospace Engineering at UC San Diego and first joined MADLab in Fall 2024. He completed his BS/MS degree also at UC San Diego, graduating in 2024. His interests lie in medical device R&D and soft robotics. During his Masters, he worked on designing, prototyping, and testing a device to improve physician ergonomics when administering colonoscopy. He is currently working on the development and fabrication of microcatheters in various applications. In his free time, he likes photography, hiking, and skiing.

Sujith Jayakumar

Sujith joined the MADLab in the fall of 2023 upon being admitted as a doctoral student in the UC San Diego Department of Mechanical and Aerospace Engineering. He earned his mechanical engineering bachelor's degree from IIITDM Kancheepuram. During that time, he worked on a theory on acoustic phenomena acting on inhomogeneous fluids and also published a comprehensive analysis of the acoustic relocation process, investigating the bidirectional coupling between the acoustic fields in the transient domain. His research interests include microscale flows, drug delivery techniques, lab-on-chip, and biomedical devices. Sujith's current work examines the acoustic streaming phenomena, which he is trying to elucidate through experiments and mathematical analysis. He aims to implement this theoretical knowledge in biological and medical domains. In his free time, he likes to play badminton, and cycle and is keen on building a social network. He is moving with MADLab to WashU.

Siyang Yu

Siyang joined the MADLab as a MS student and transferred to a PhD student in the winter quarter of 2024 from Department of Mechanical and Aerospace Engineering at UC San Diego. He received his Bachelor's degree in Engineering Mechanics from Shanghai Jiao Tong University in 2022. He studied in the field of biomechanics and fluidmechanics during his undergraduate project, including the effect of red blood cells on movement of CTCs, designing boinic robots and deep-sea monitoring system driven by wave energy. His research interests lies in small scale fluidmechanics and biomechanics. He is currently working on optical measurement of nanoscale fluid behavior and nanofiber acoustic sensors. In his daily life, he loves ping pong, playing acoustic guitar and cats. He is moving with MADLab to WashU.

Kha Nguyen

Kha is a newly admitted Ph.D. student in the department of Mechanical and Aerospace Engineering at UC San Diego. She graduated from UC San Diego with a B.S. in Bioegnineering in 2021. During her undergraduate study, she did research in diverse fields, including designing, rapid prototyping, and evaluating prosthetics for quadrupeds and humans, designing and implementing 3D speckled imaging for strain measurements in torsion, analyzing retinal implants data, and creating an automatic microfluidic system for brain and retinal organoid culturing. Her research interest includes retinal implants, ocular health monitoring systems, wearable sensors, soft robotics, and surgical devices R&D. In her free time, she loves learning about skincare, hedgehogs, how to deadlift correctly, and decoding the latest memes.

Lei Zhang

Lei is a PhD student in the Department of Mechanical and Aerospace Engineering at UC San Diego. She received her Bachelor’s degree in Biomedical Engineering from Nanjing University in 2021. During her undergraduate study, she explored the field of nanotechnology and materials for medical application, including efficient self-assembling nanocomposite platform for cancer photothermal therapy and imaging, medical device based on superparamagnetic nanoparticles for CTCs diagnosis and stretchable bioelectronics of skin sensor based on liquid metal. Her research interests include bioelectronics and disease diagnostics. She’s currently working on surface acoustic wave devices for clinical applications. Also, she loves playing badminton, board games and hiking with friends.

Professor James Friend

James leads the Medically Advanced Devices Laboratory in the Center for Medical Devices at the University of California-San Diego. He is the incoming Chair of the Department of Mechanical Engineering and Materials Science at Washington University in St. Louis, Missouri. Until November 2025, he was a professor in the Department of Mechanical and Aerospace Engineering, and held the Stanford S. and Beverly P. Penner Endowed Chair in Engineering.

He has over 300 peer-reviewed research publications, including 205 journal papers and nine book chapters, and 35 patents in process or granted, completed 34 postgraduate students and supervised 23 postdoctoral staff, and been awarded over $29 million in competitive grant-based research funding over his career. He is a fellow of the IEEE and the Royal Society of Chemistry. More information here.

Dr Aditya Vasan (CEO, SonoBac, San Diego)

Dr Phuong Truong (Research Fellow, UCSD San Diego)

Mr Oscar Yau Yun (UCSD Medical School)

Dr Jeremy Orosco (Researcher, HRL Laboratories, Malibu, CA)

Dr Amihai Horesh (Researcher, Volcani Institute, Israel)

Dr Gopesh Tilvawala (Research Staff, Abbott Medical)

Prof Yuta Kurashina (Tokyo University of Agriculture and Technology)

Dr William Connacher (Staff, Sonocharge, San Diego)

Dr An Huang (CEO, SonoCharge, San Diego)

Dr Naiqing Zhang (Huawei, Shanghai, China)

Prof Lonnie Petersen (MIT Institute for Medical Engineering and Science)

Jackelin Amorin Cotrina (Researcher, UC San Diego)

Prof Kenjiro Takemura (Keio University, Japan)

Dr Morteza Miansari (San Francisco Bay)

Dr Sean Collignon (Dallas Texas)

Dr Jiyang Mei (Gener8, Carlsbad, CA)

Prof Cécile Floer (Uni Lorraine, Nancy, France)

Edward Aminov (Apple Inc)

Facilities

Overview

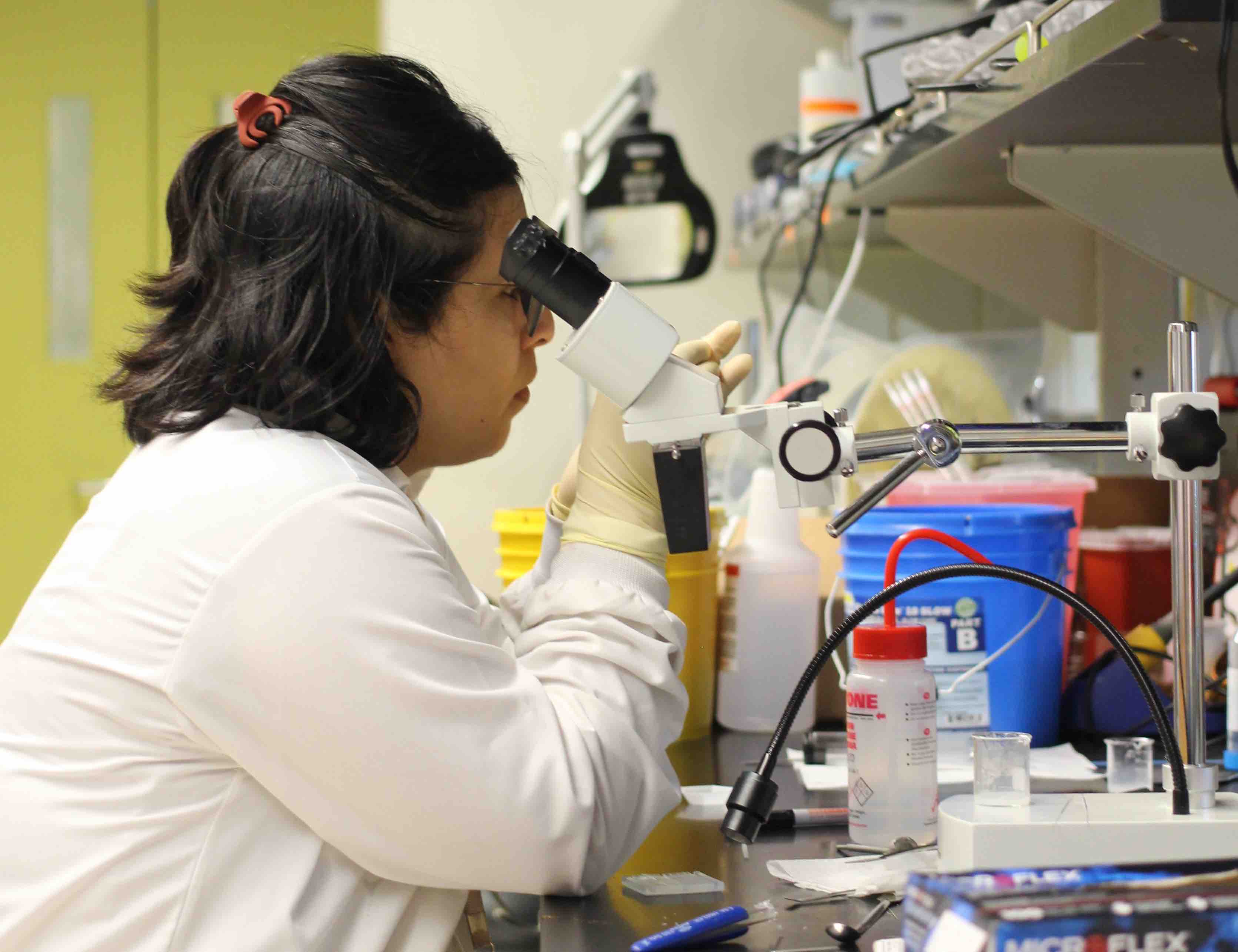

The 100 sqm (1050 sqft) MADLab laboratory includes fabrication, prototyping, metrology, and testing facilities. We make daily use of the extraordinary NANO3, Qualcomm Institute, and ACTRI core facilities.

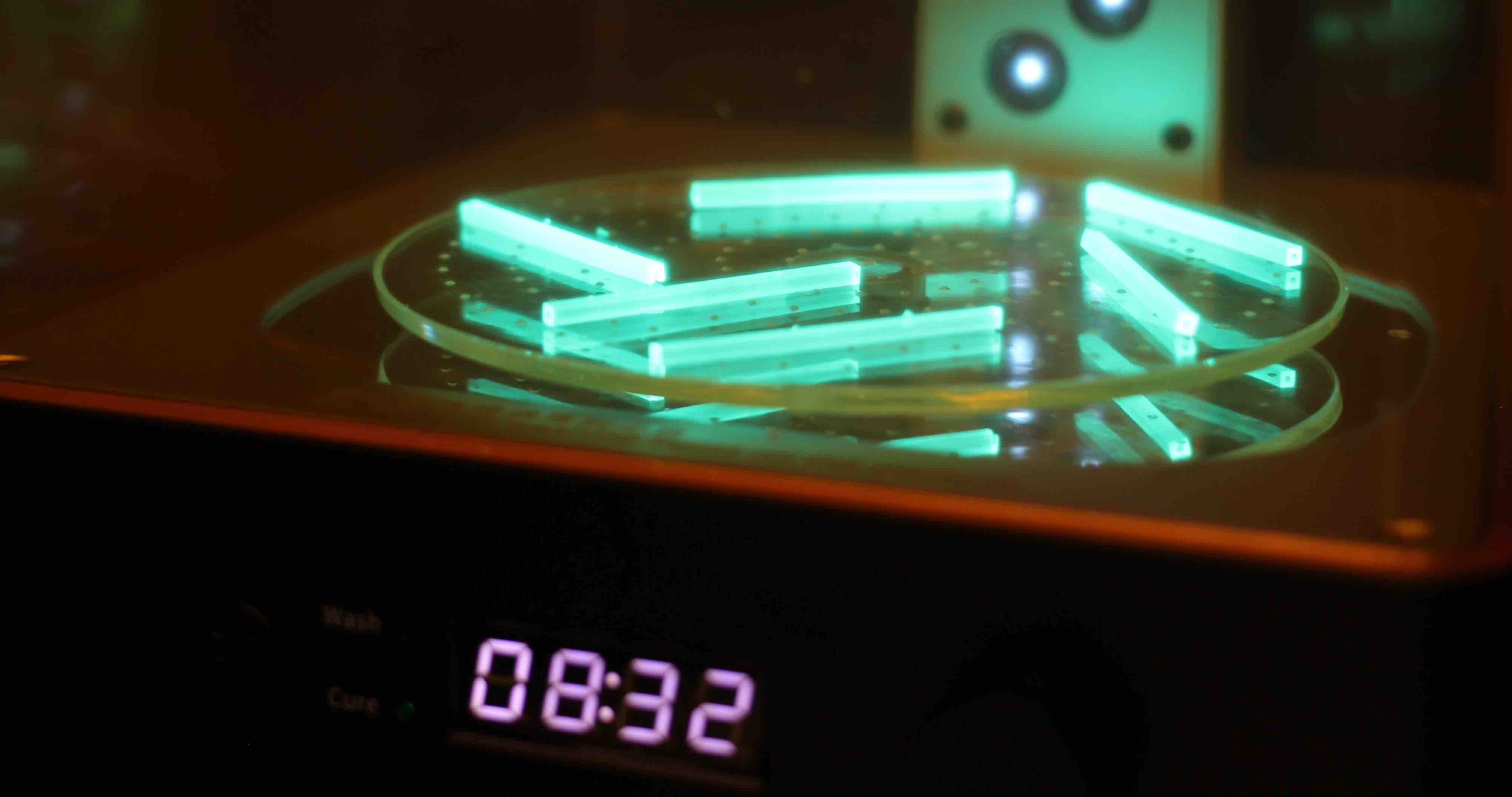

Fabrication facilities: laser machining

We have access to a customized Optec Lightshot excimer (193nm, 25 J/cm^2) + femtosecond (1030nm, 20W) five-axis CNC, arbitrary mask laser machining station from Optec, and is capable of machining lithium niobate, glass, all polymers, and metals. It is capable of achieving feature sizes smaller than 750nm. John Roy, an experienced local representative is often on site for training and advice. cleanroom equipment for polymer microfabrication, including a large fume hood, argon-purged glove box, class 1000 laminar flow cabinet with UV shielding for photoresist work, vacuum and dessicator stations for polymer microfabrication, extrusion, plasma etching, spin coating, casting, and integration.

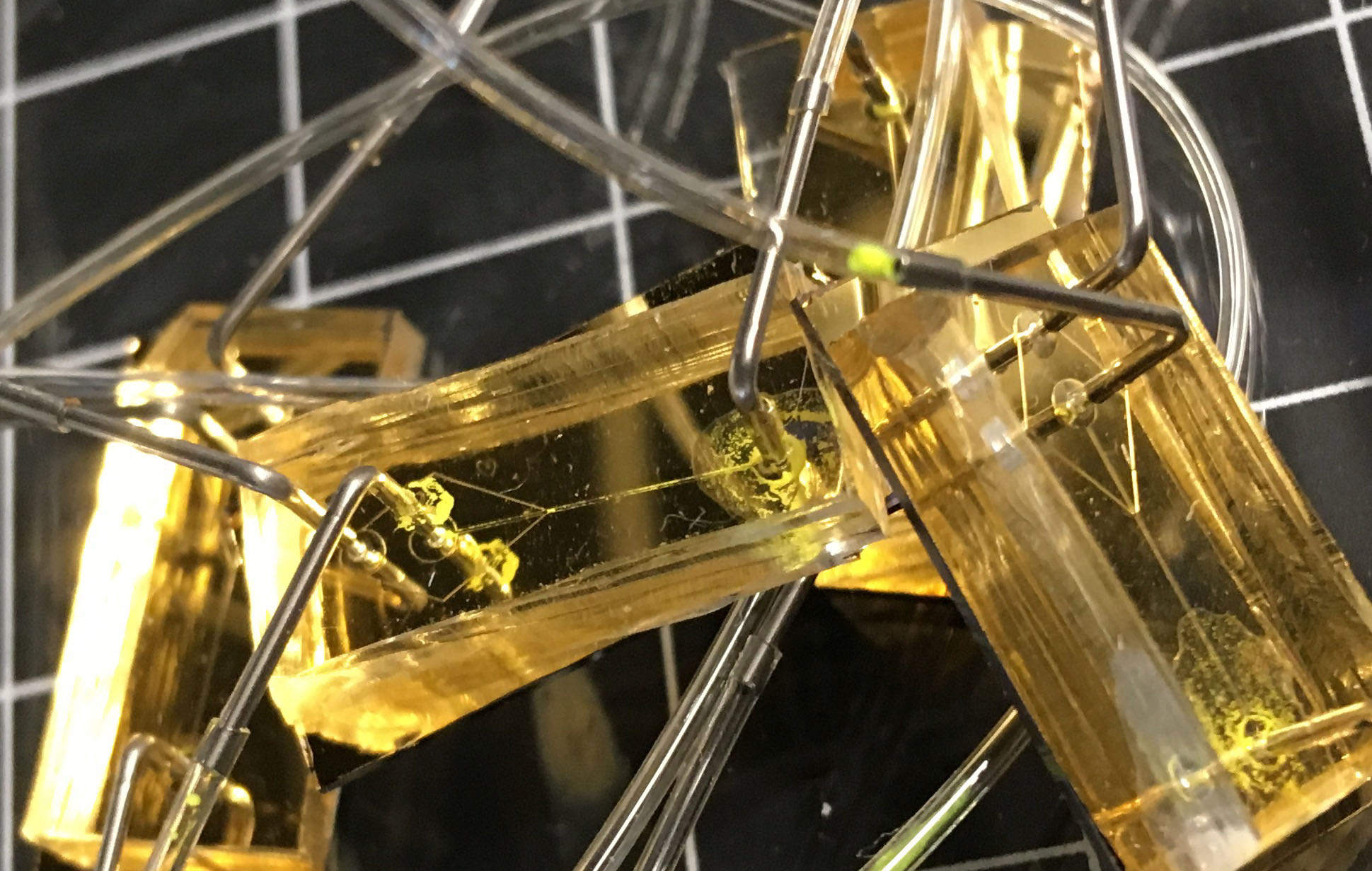

Fabrication facilities: microfluidics, microscale soft robotics, and integrated microelectromechanics devices

The lab has four microassembly/microscopy stations complete with pantograph micromanipulators and custom ultrasound-based pick-and-place manipulators. We also have two microsoldering stations with wave and SMD device soldering systems., and a microassembly and testing station with pantograph micromanipulators. The lab also has a DC-2.4GHz four-port network analyzer and numerous oscilloscopes, signal generators, and amplifiers.

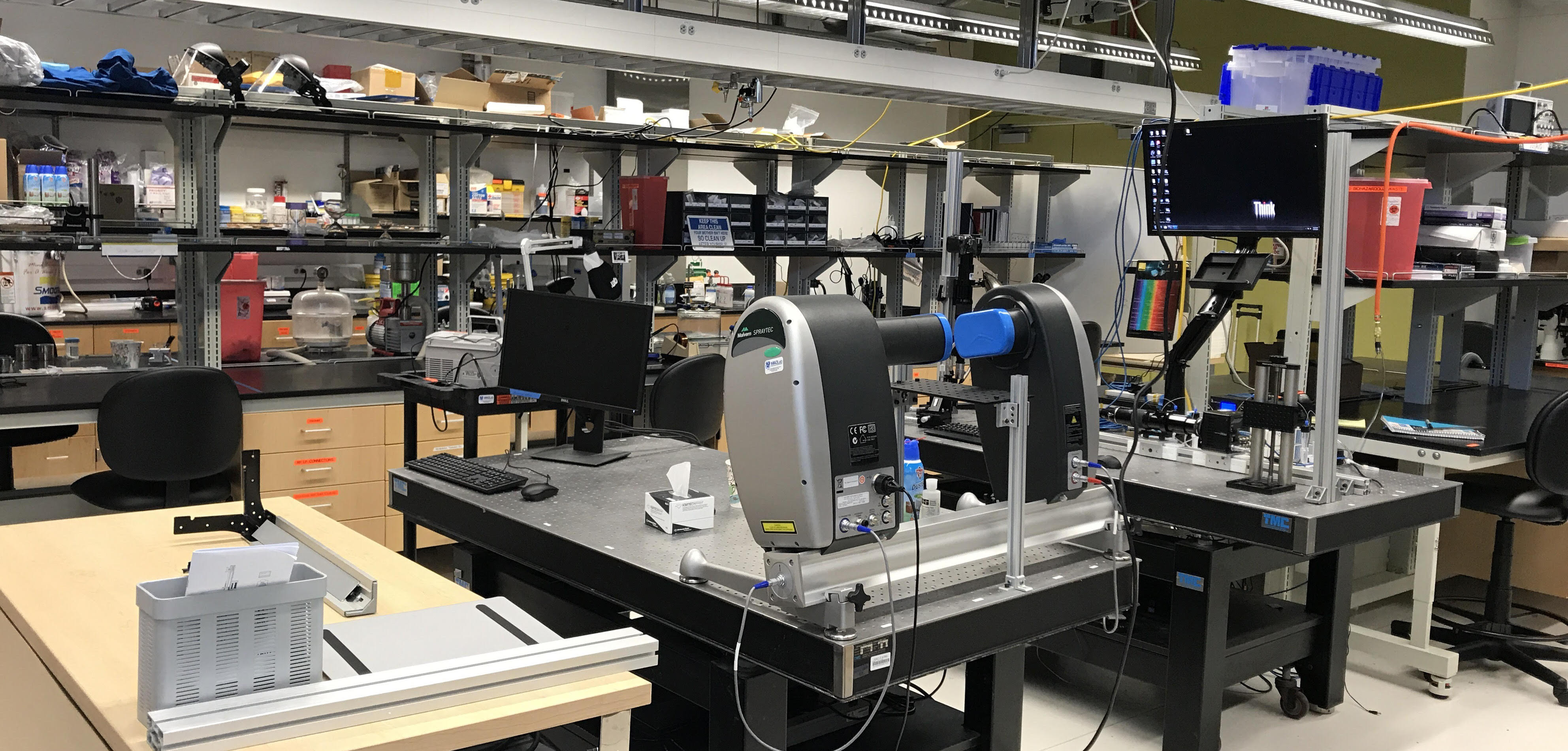

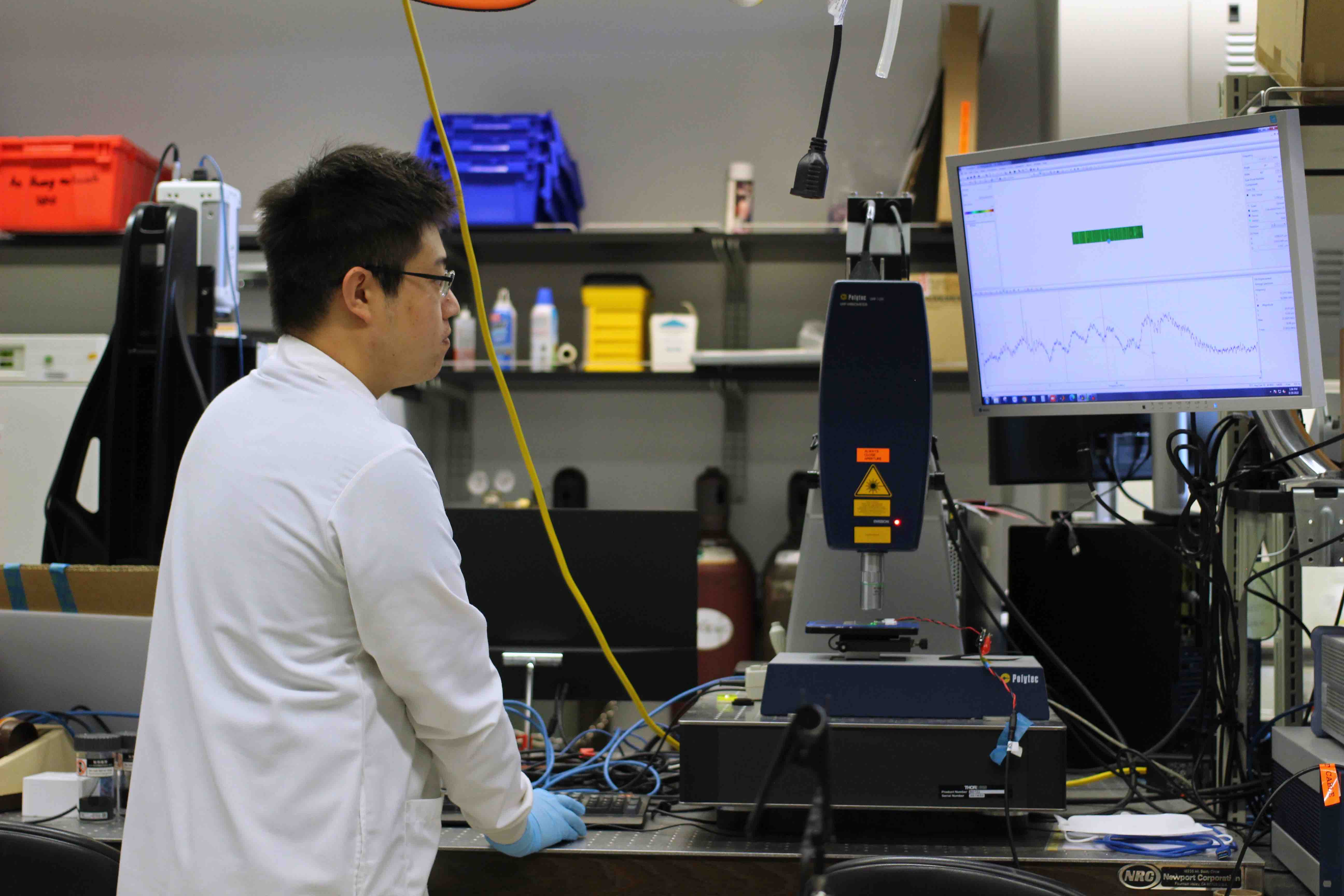

Metrology: high-speed videography, vibration and velocity measurement, and pressure and acoustic field measurement

The lab has a unique high-speed transmission digital holographic microscope (DHM) system from Lyncée-tec. The system offers the ability to measure fluid interface and cell membrane motion to 100 kHz real-time and continuously over the entire field of view at 1MP resolution to 3 µm lateral resolution and 10 nm displacement resolution. This system was responsible for our discovery of the mechanism driving ion channel activation in sonogenetics from ultrasound. It includes a 1.2 million fps, Photron NOVA camera.

The lab also has a 9 kHz–2.4 GHz scanning laser Doppler vibrometer, Polytec UHF-120SV, able to measure 9 kHz to 2.4 GHz acoustic wave propagation upon micro to submicron devices and a laser Doppler tachometer, Canon LV-100Z, able to measure in-plane motion to 10 m/s and 2 kHz. Due to excellent support by Polytec Irvine, the laboratory has regular access to other vibrometer and surface metrology capabilities as needed.

Wel also have a Malvern Spraytec atomized mist sizer with fixturing for nebulizers and fuel injectors.

We have fluorescent and bright-field high-speed (Photron UX100+Infinity TS) video microscopes; and microfluidics control and operation equipment (ELVEFLOW); an inverted phase contrast, epifluorescence and TIRF microscope (AmScope).

Our lab also has extensive electrical test gear, from network analyzers to lock-in amplifiers, RF arbitrary signal generators, and amplifiers.

Funding

Teaching

Helping train the next generation of engineering and scientific leaders

The group serves UCSD by teaching engineering design, dynamics, structural and fluid mechanics, acoustofluidics, micro to nano-scale fabrication, and medical device engineering courses at the undergraduate and graduate level.

MorePrincipal Investigator: Professor James Friend

Phone/Zoom: +1-858-26o-95o8 • https://ucsd.zoom.us/j/8582609508

Faculty Assistant: Samantha Drumb

Center for Medical Devices

Department of Mechanical and Aerospace Engineering • Jacobs School of Engineering

Department of Surgery • School of Medicine

University of California, San Diego

9500 Gilman Drive MC0411

La Jolla, CA 92093-0411

Offices: 344K/345C&F Structural and Materials Engineering Building

Lab: 320 Structural and Materials Engineering Building

Maps to parking, laboratories and offices.

Shipping address:

University of California, San Diego

Attn: Prof James Friend, (858) 260-9508

320 SME MC0411

7835 Trade Street

San Diego CA 92121-2460

Copyright notice

Work(s) (the “Work”) by:

COVID-19 Acute Ventilation Rapid Response Taskforce (AVERT) Medically Advanced Devices Laboratory

Department of Mechanical and Aerospace Engineering

Jacobs School of Engineering and the School of Medicine University of California, San Diego

9500 Gilman Drive MC411

La Jolla, CA 92093-0411

This Work is Copyright © 2020 The Regents of the University of California. All Rights Reserved. Permission to copy, modify, and distribute this Work and its documentation for educational, research and non-profit non-clinical purposes, without fee, and without a written agreement is hereby granted, provided that the above copyright notice, this paragraph and the following three paragraphs appear in all copies. Permission to make commercial and/or clinical use of this Work may be obtained by contacting:

Office of Innovation and Commercialization

9500 Gilman Drive, Mail Code 0910

University of California

La Jolla, CA 92093-0910

(858) 534-5815

innovation@ucsd.edu

This Work and documentation are copyrighted by The Regents of the University of California. The Work and documentation are supplied “as is”, without any accompanying services from The Regents. The Regents does not warrant that the operation of the Work will be uninterrupted or error-free. The end-user understands that the Work was developed for research purposes and is advised not to rely exclusively on the Work for any reason.

IN NO EVENT SHALL THE UNIVERSITY OF CALIFORNIA BE LIABLE TO ANY PARTY FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS, ARISING OUT OF THE USE OF THIS WORK AND ITS DOCUMENTATION, EVEN IF THE UNIVERSITY OF CALIFORNIA HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. THE UNIVERSITY OF CALIFORNIA SPECIFICALLY DISCLAIMS ANY WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE WORK PROVIDED HEREUNDER IS ON AN “AS IS” BASIS, AND THE UNIVERSITY OF CALIFORNIA HAS NO OBLIGATIONS TO PROVIDE MAINTENANCE, SUPPORT, UPDATES, ENHANCEMENTS, OR MODIFICATIONS.